- Select a language for the TTS:

- UK English Female

- UK English Male

- US English Female

- US English Male

- Australian Female

- Australian Male

- Language selected: (auto detect) - EN

Play all audios:

The low liquid limit silty soil in the North China plain area is generally unsuitable for direct use as roadbed and slope soil. In order to improve the performance of low liquid limit silty

soil, xanthan gum was used as an improver. Through a series of tests, the improvement effect of xanthan gum on low liquid limit silty soil was studied. The test results showed that Xanthan

gum as an improver could significantly improve the unconfined compressive strength of silty soil. With the increase in dosage and curing age, the unconfined compressive strength of improved

silty soil continued to improve and eventually tended to stabilize. The optimal dosage and curing period were 2% and 7 days, respectively. In addition, Xanthan gum could greatly improve the

permeability and disintegration of low liquid limit silty soil. The permeability coefficient of improved silty soil with a content of 0.75% Xanthan gum and a 7-day curing period was 4.73 ×

10−4 m·s−1, which was only 1.10% of that of plain silty soil at the same curing period. After immersion in water for 12 h, the soil only experienced slight disintegration. The scanning

electron microscope image showed that the gel generated by the hydration reaction of Xanthan gum could improve the compactness and integrity of the soil by filling the voids, thus

significantly improving the mechanical and hydraulic properties of the low liquid limit silty soil.

In the Yellow River alluvial plain of China, there is a large amount of low liquid limit silty soil, with silt particle content generally reaching over 50% and clay particle content less

than 10%. The special composition of soil particles determines its unique engineering performance. This type of silty soil has a low liquid limit, low strength, and extremely poor water

stability, and is generally not suitable for use as a roadbed1. Therefore, the efficient low liquid limit silty soil improvement methods have always been an important challenge in

engineering construction.

There are two main methods of soil improvement: physical and chemical improvement techniques. The physical improvement techniques are mainly achieved through replacement and compaction2. The

soil replacement will waste a large amount of land resources, which does not meet the requirements of ecological and environmental protection. In addition, silty soil has low plasticity,

poor cohesion and low strength, which makes it difficult to achieve the desired compaction level. At present, the chemical improvement techniques have been widely used in the field of

geotechnical engineering. The cement, lime, asphalt, etc. are the most commonly used chemical improvement materials. However, the mass production and use of chemical improved materials have

brought many environmental problems3,4,5. Therefore, it is necessary to use efficient and environmentally friendly materials to improve the soil.

The biopolymers are polysaccharides with a polymer chain structure. It is derived from natural resources and has a wide range of uses. Due to its rheological and pseudoplastic properties, it

has been widely used as a thickener or emulsifier in food and medical products6. In the field of environmental engineering, the biopolymers are used for soil improvement7. In addition, the

biopolymers are also used in the petroleum industry to guide the flow of oil8, as well as for crack repair in concrete9. The biopolymers have also received widespread attention in the field

of geotechnical engineering due to their high efficiency in soil improvement and low environmental impact10. The research results indicate that11,12,13,14,15, guar gum, gellan gum, chitosan

and carboxy methyl cellulose can effectively improve the strength of soil. Loose soil particles could be tightly bonded by Xanthan gum, therefore, the permeability of the improved soil was

reduced, and the ability to resist hydraulic and wind erosion was enhanced16,17,18,19. In addition, the biopolymers are rich in carbon and nitrogen elements, which can provide nutrients for

soil and promote plant growth. Therefore, the biopolymers can be used for slope vegetation protection and land desertification prevention20,21,22. Although the research results are

encouraging, the biopolymers have not been widely used in the field of geotechnical engineering due to their market cost, on-site application conditions and methods, durability, and

sensitivity to water23. Especially, xanthan gum can better adapt to different temperature and pH conditions24, and compared with other biopolymers, it has a larger production volume and

relatively lower price25. As a green material, it has been used to improve various poor soils, such as high liquid limit coarse-grained soil26, clay27,28,29, sandy soil30, organic peat

soil31 etc. The mechanical parameters such as unconfined compressive strength and shear strength of the improved soil have been significantly improved. Latifi et al.32 used Xanthan gum as an

improver to treat cohesive soil, and the cohesive force of the improved soil was significantly increased. Chang et al.33 pointed out that the Xanthan gum has a better reinforcement effect

on well graded soil, and the reinforcement effect mainly depends on four factors: soil type, xanthan gum content, curing age, and mixing method. The results of Ahmadi et al.34,35,36 showed

that the cleaning improver such as xanthan gum can significantly improve the mechanical properties of soil after dry–wet cycle (W–D) and freeze–thaw cycle (F–T). Kumar et al.24 confirmed

that the Xanthan gum is more efficient in reducing soil permeability compared to guar gum and pectin. Ghasemzade et al.37 conducted research on a new cleaning biopolymer. The results

confirmed that Persian gum has successful properties in terms of bonding soil particles, pore filling, thermal stability, etc. Additionally, consuming smaller amounts of Persian gum in the

presence of calcium chloride can make stabilization projects cost-effective37,38.

The Xanthan gum was selected as an improved material in this study, based on its wide applicability and low cost advantages. Currently, the research on xanthan gum-improved soils mainly

focuses on sand and clay, with less attention paid to low liquid limit silty soil. In addition, most of the research has focused on the enhancement of the mechanical properties of soils,

while less research has been conducted on the hydraulic properties, especially the collapse resistance, under geotechnical application conditions. The resistance of soils to disintegration

is closely related to the protection of side slopes under rainfall conditions. The Xanthan gum was used to improve low liquid limit silty soil, and unconfined compressive strength tests,

permeability tests, and wet disintegration tests were conducted. The influence of Xanthan gum on the mechanical and hydraulic properties of improved silty soil was studied, and its

solidification mechanism was analyzed. The research results further enriches the method of roadbed improvement for low liquid limit silty soil. It provides an important theoretical basis for

the application of xanthan gum in the engineering construction of such silty soil areas as well as the slope protection project.

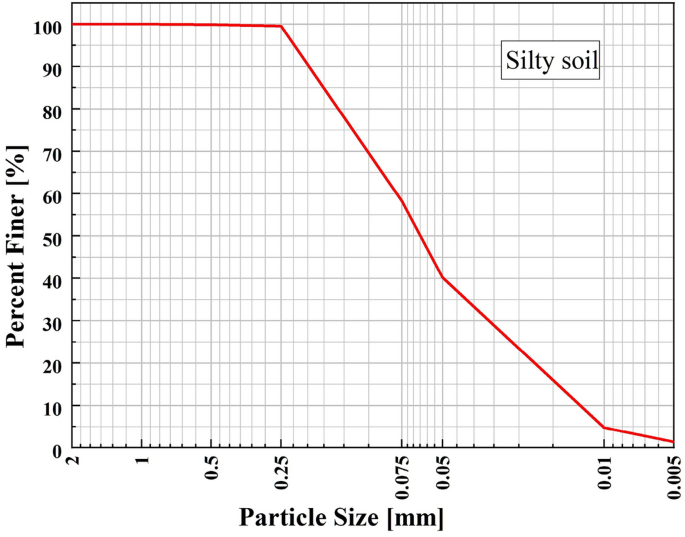

The basic physical indexes of the low liquid limit silty soil in this study are as follows: the liquid limit is 24.1%, the plastic limit is 15.4%, the plasticity index is 8.7, the optimum

moisture content is 14.9%, the maximum dry density is 1.72 g/cm3, the specific gravity is 2.68, and the saturated moisture content is 40.45%. The content of soil particles with a grain size

of less than 0.075 mm is 58.2%. The plasticity index of the soil is less than 10, the mass of particles larger than 0.075 mm does not exceed 50% of the total weight, and the liquid limit is

less than 50. Therefore, the soil is defined as a low liquid limit silty soil. The content of soil particles with a particle size greater than 0.075 mm was less than 50%. Most of the soil

particles were silty soil particles and a small number of sand particles and clay particles. When dry, the soil blocks are not firmly bonded enough, and can be rubbed by hand to form powder

without any sticky feeling. When moist, it has fluidity and can be squeezed into a ball in the hand. The particle grading curve is shown in Fig. 1.

The Xanthan gum is a polysaccharide produced by the fermentation of glucose or sucrose by Xanthomonas flavus39. It consists of two glucose, two mannose and one glucuronic acid unit. It is

readily soluble in water, but insoluble in organic solvents such as ethanol, and has high viscosity rheological properties when dissolved in water. Xanthan gum used in this study was

produced by Baikang Foods Factory and purchased from a retailer. It is 99.7% pure, light yellow powder (Fig. 2) and the pH value of 1% xanthan gum solution is 7.8. It should be sealed during

storage to avoid moisture.

The dried and crushed silty soil is mixed evenly with a certain amount of Xanthan gum. Pure water is added to the mixed soil according to the optimal moisture content and stirred evenly. The

mixed soil is sealed with plastic film. After 12 h, the water in the soil migrates uniformly, and then the soil specimen is prepared using the static pressure method. The soil specimens

preparation instrument is shown in Fig. 3. To prepare the unconfined compressive specimen, the soil mixture was divided into three parts and poured sequentially into the mold for compaction.

Then the specimen was pressed out with the soil extraction device for demolding. A standard cylindrical specimen with a height of 80 mm and a diameter of 39.1 mm was obtained as shown in

Fig. 4a. The permeable soil specimen, which did not need to be demolded, was a 61.8 mm cylinder with a height of 40 mm, as shown in Fig. 4b. The disintegration test specimens were made into

95% compacted soil using a compaction device (same compaction as the above specimens), and amended to cubes with sides of 50 mm using a soil trimmer as shown in Fig. 4c. The soil body was

avoided to be disturbed during the amendment process. The prepared earth samples were placed in a conservation box at a temperature of 25 ± 2 °C and 50% relative humidity and maintained to

the appropriate age. Conduct the corresponding tests and record the test data according to 36.

To investigate the effects of Xanthan gum content and curing age on the mechanical and hydraulic properties of the improved silty soil, the unconfined compressive strength test, permeability

test, and wetting disintegration test were carried out. To analyze the solidification mechanism of Xanthan gum improved silty soil, the scanning electron microscopy experiments were carried

out. The content of Xanthan gum and curing age of the soil specimens are detailed in Table 1.

The unconfined compressive strength test was carried out by the electronic universal testing machine. The maximum range of the testing machine was 10 kN. The test was carried out with equal

strain loading at a loading rate of 1 mm/min. When the pressure reached the peak, continued to add 3–5% strain until the soil sample was completely destroyed. During the experiment, the

pressure and deformation of the soil specimens were tested. The data were averaged and analysed to reduce the error. The specimens with excessive errors were excluded to ensure that

compressive strengths of the three parallel specimens did not exceed 10% of their mean values.

In geotechnical engineering, seepage can cause deformation of soil and have adverse effects on the stability of geotechnical structures. The influence of Xanthan gum content and curing age

on the permeability performance of improved silty soil was studied using the WST-2 Falling Head Permeameter (Fig. 5). The test procedure are as follows:

Apply Vaseline to the inner wall of the sleeve, install the saturated soil specimen into the sleeve, press in the waterproof gasket, and install the permeable stone. Then tighten the upper

and lower covers to ensure no air or water leakage.

Connect the infiltration container with the water head device, inject water into the infiltration container, remove the air from the container. The test began after the water from the outlet

pipe was stable.

During the test, the head was filled to a certain height, and the starting head h1 and the starting time t1 were measured. After an interval of time t, the head h2 was measured. The starting

and ending water temperatures were recorded. Repeat the test 5 times for each specimen. Finally, averages were taken and analyzed, and it was ensured that each test result was within 10% of

the average.

The disintegration of soil is caused by the infiltration of water, which weakens the bonding force between soil particles and leads to the disintegration of the soil. The disintegration rate

can be used as an indicator to determine the water stability of soil. The wetting disintegration instrument consists of a water container, a hanging net, and a float bowl, as shown in Fig.

6. During the test, the silty soil specimen is placed on a hanging net and then placed in a water container. After a period of time, the reading of the float bowl is recorded. The

disintegration rate is calculated using the following formula:

where Nt—disintegration rate of soil specimen at t time (When Nt > 0, the soil specimen exhibits mainly water absorption. When Nt

:max_bytes(150000):strip_icc():focal(265x0:267x2)/terri-cosby-1-e31ca72dc39540eb9aff42e4207ddfc6.jpg)

:max_bytes(150000):strip_icc():focal(999x0:1001x2)/rossi-lorathio-adam-1-2000-dd8885a1d07449188e1d8844b5b02d50.jpg)

:max_bytes(150000):strip_icc():focal(639x0:641x2)/chris-janson-56fcead2ffd84856b5f09b5239270e8a.jpg)