- Select a language for the TTS:

- UK English Female

- UK English Male

- US English Female

- US English Male

- Australian Female

- Australian Male

- Language selected: (auto detect) - EN

Play all audios:

ABSTRACT We indicated high performance and stability transparent heaters based on AlOx covered Ag nanowires. We obtained an AlOx covered Ag nanowire thin film which has a 47 ohm/sq of sheet

resistance and 88.1% (substrate included) of transmittance at 600 nm on a flexible substrate. We demonstrate that the thin AlOx layer leads to increased contact area at the junction of Ag

nanowires, which contributes to lower sheet resistance and improved adhesion of Ag nanowires. Furthermore, high stability and flexibility of Ag nanowire have been achieved by the AlOx layer.

Finally, we fabricated a flexible transparent heater with AlOx covered Ag nanowire, and obtained a temperature of 81 °C within 40 sec at the driven voltage of 7 V with fast response and

uniform temperature distribution. Therefore, the AlOx covered Ag nanowire film is a promising candidate for the application of the flexible transparent heaters. SIMILAR CONTENT BEING VIEWED

BY OTHERS FAST, FACILE AND THERMAL DAMAGE FREE NANOWELDING OF AG NANOWIRE FOR FLEXIBLE TRANSPARENT CONDUCTIVE FILM BY PRESSURE-ASSISTED MICROWAVE IRRADIATION Article Open access 01 September

2023 ULTRA-HIGH TEMPERATURE TOLERANT FLEXIBLE TRANSPARENT ELECTRODE WITH EMBEDDED SILVER NANOWIRES BUNDLE MICROMESH FOR ELECTRICAL HEATER Article Open access 20 June 2022 CHEMICALLY-STABLE

FLEXIBLE TRANSPARENT ELECTRODE: GOLD-ELECTRODEPOSITED ON EMBEDDED SILVER NANOWIRES Article Open access 16 October 2023 INTRODUCTION Transparent heaters are commonly used in a wide range of

applications such as solar panels, vehicle defrosters, periscopes, and smart, heat-retaining windows. Especially, the future direction of flexible transparent heaters focuses on anti-fogging

windshields, mirrors, and displays ensuring the fast response of electronic devices under cold and icy environmental conditions1,2,3,4. For a high-performance transparent heater, a high

quality transparent conductive material is essential. In order to meet the requirement of high conductivity with transparency and flexibility, carbon-based materials (graphene, carbon

nanotubes (CNTs))5,6,7,8,9,10,11, conducting polymers12,13,14,15, metal nanoparticles16, and metal mesh17,18,19 have been widely used for a flexible substrate. Although the flexibility of

these transparent conductors is greatly improved, their performance highly depends on the sample preparation and often does not meet the requirement for many applications regarding

conductivity and stability20,21,22. However, metal nanowires (NWs) in the form of randomly percolation network have shown excellent potential as flexible transparent

conductors23,24,25,26,27,28,29. Thus, metal nanowires with low resistance, high transmittance and stability are very important parts for future applications. Especially, AgNW-based

applications have been actively researched because of its exceptional properties: LED array, touch-panels, displays, anti-counterfeit devices, energy harvester, skin attachable and

implantable sensors, flexible and stretchable transparent heaters30,31,32,33,34,35,36. However, in the case of a metal nanowire, many researchers have realized the serious problem of metal

corrosion37,38. Furthermore, the poor adhesion of metal network to the substrate limits its wide applications23,39, high stability against humidity and period of metal nanowires have not yet

been achieved simultaneously for transparent conductive materials. Hwang _et al_. reported that a 5.3 nm thickness Al2O3 using atomic layer deposition (ALD) method can improve the thermal

and mechanical stability of Ag nanowire electrodes40. However, ALD is not suitable for mass production because of a time-consuming process and toxic chemicals. And its higher temperature

process over 100 °C limits a variety of flexible substrates. To overcome these problems, we investigated the effect of the AlOx protection layer on Ag nanowires using physical vapor

deposition (PVD) method to gain a good adhesion and stability with high transmittance and conductivity. The whole process was carried out at room temperature without any annealing process

and chemical treatment. Comparison with Ag nanowires, electrical properties and adhesion of AlOx covered Ag nanowires were improved, AlOx covered Ag nanowires can be obtained without serious

conductivity and transmittance loss. Finally, we demonstrate the fabrication of a highly transparent, conductive, and stable AlOx covered Ag nanowires based on a flexible transparent

heater, 81 °C of temperature within 40 sec at the driven voltage of 7 V has been achieved. These results are a promising application for the flexible transparent heater. The results show

that the AlOx protection layer on Ag nanowires can significantly reduce the sheet resistance and increased stability of Ag nanowires, which can enhance heat generation behavior and duration

of usage for flexible transparent heater applications. EXPERIMENTS AgNWs were coated on a 100 _μ_m-thick Polyethylene terephthalate (PET) substrate by a drop-casting method. Then, the coated

substrate was dried for 30 sec in the air wind with a temperature of 60–65 °C and a velocity of 17 m/s41. The typical diameter of AgNWs (NANOPYXIS Inc.) was 30 nm and their length was 5~10

μm. The AgNWs were dispersed in Isopropanol (IPA) with a concentration of 0.15 wt%. After we made the AgNWs on the PET substrate, we deposited AlOx with a radio frequency (RF) power of 700 W

in the vacuum chamber with the 3.5 mTorr of working pressure. Al target (99.99%) was used for the deposition, Ar-diluted O2 gas (5%) was used for reactive sputtering deposition. The sheet

resistance of the AgNWs was measured using a four-point probe. Surface morphology images of the samples were obtained using a field-emission scanning electron microscopy (FE-SEM). The

optical transmittance was measured in the wavelength range of 400–1000 nm by UV-spectrophotometer. The material components of the thin films were analyzed by using energy dispersive

spectrometry (EDS) and X-ray photoelectron spectroscopy (XPS). The mechanical adhesive force was tested using 3 M SCOTCH MAGIC tape, No. 810 (adhesion strength to steel, 2.737 N/cm)42. To

explain reliability for moisture, the AgNWs films were stored in a thermos-hydrostatic chamber (WEISS WK11 340) for 120 h with a temperature at 85 °C and relative humidity 85%. The voltage

source was connected to both edges of the aluminum foil electrode. The temperature and the thermal image of the surface were obtained by a thermal imaging camera (FLIR, TI480). RESULTS AND

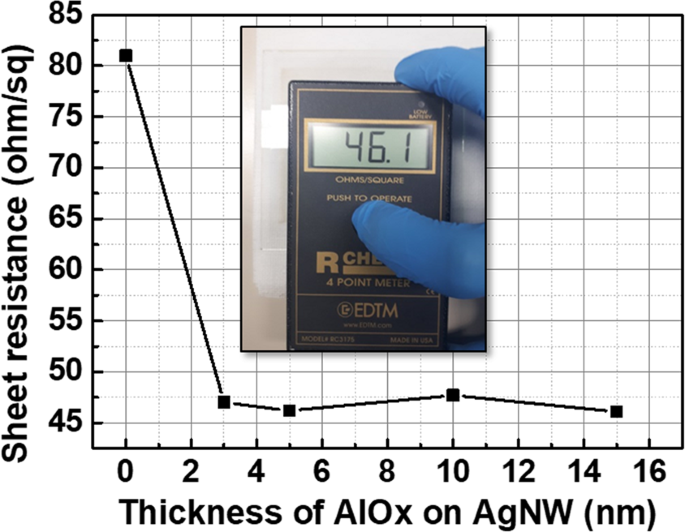

DISCUSSION Figure 1 shows the variation of the sheet resistance of AgNWs as a function of AlOx thickness. As shown in Fig. 1, the sheet resistance of the AgNWs decreased after 3 nm-thick

AlOx deposition from 81 ohm/sq to 47 ohm/sq. Then, regardless of AlOx thickness, the sheet resistance of AlOx covered AgNWs were almost the same with 3 nm-thick AlOx covered AgNWs. These

results indicate that AlOx thicknesses (3~15 nm) are not related to the sheet resistance of AgNWs. Figure 2 shows the change of transmittance of the AgNWs/PET substrate with various AlOx

thickness. As shown in Fig. 2, the transmittance (in the whole visible range) of the AgNWs/PET substrate did not change after AlOx deposition. Although the sheet resistance of AgNWs

dramatically decreased after AlOx deposition, transmittances did not decrease much after AlOx deposition. Moreover, AgNWs indicate high transparency in the whole visible and infrared range

as shown in Fig. 2. These results mean that the AlOx layer does not negatively affect an optical property because AlOx is very transparent. Lots of papers reported that Ag nanowire has a

trade-off relationship between transmittance and sheet resistance43,44. However, we indicate improved electrical properties of AgNWs using the AlOx layer without transmittance loss. To

demonstrate the improved electrical properties without the reduction of transmittance after AlOx deposition on the AgNWs, we analyzed surface morphology using an FE-SEM as shown in Fig. 3.

Figure 3(a) shows the AgNWs film on the PET substrate. The AgNWs dispersed randomly on a PET substrate, uniformly interconnected AgNWs were formed on a substrate. The contact area at the

junction of AgNWs is the dominant factor determining the sheet resistance of AgNWs films45. The contact area of AgNW junction parts is small as shown in Fig. 3(a), this result leads to low

electrical conductivity. Figure 3(b) shows the SEM image of 3 nm-thick AlOx on dispersed AgNWs. We indicate that after the deposition of AlOx on AgNWs, the contact area of AgNWs junction

parts was increased. We expect that plasma energy and a thin film deposition using PVD method reduced the stiffness of AgNWs, the phenomenon leads to increased the contact area of the AgNWs

junction41,46. As expected from SEM results, the increased contact area of AgNWs junction parts leads to a decrease in the sheet resistance of AgNWs without a reduction of transmittance. EDS

measurements were carried out to evaluate the chemical composition of the AlOx thin film. As shown in Fig. 4, EDS confirms that AgNWs and AlOx covered AgNWs contains Ag, O, Si peak and Al,

Ag, O, Si peak, respectively. To demonstrate the stoichiometry of the AlOx layer, 3 nm-thick AlOx was analyzed using XPS. As a result, the XPS survey spectrum is presented in Fig. 5. The XPS

survey spectra of 3 nm-thick AlOx represent mainly Al, O, and C contributions. The binding energy peak of 74 eV indicates Al2p and O1s show ~531 eV peak. Thus, we investigated that Al2O3

thin film has been deposited by reactive sputtering. We confirmed that the Al2O3 dominantly existed in the AlOx protection layer. To compare the adhesion of AgNWs with and without the AlOx

protection layer, a tape test was carried out as shown in Fig. 6. As shown in Fig. 6(a), the AgNWs without the AlOx layer was easily detached from the PET substrate because of the weak

binding energy of the AgNWs on the flexible substrate, and the sheet resistance of detached parts highly increased (∞ ohm/sq). In contrast, the AlOx covered AgNWs exhibited an improvement of

adhesion due to the AlOx protection layer, and the sheet resistance did not change after the taping test as shown in Fig. 6(b). In order to confirm the effect of moisture and temperature,

AgNWs with and without AlOx coating layer were exposed to high temperature and high humidity condition (85 °C, 85%) for 120 h after an outer bending test with radius of a 5 mm and 1000

cycles as shown in Fig. 7. Figure 7(a) shows the transmittance of AgNWs with and without the AlOx layer as a function of humidity time at 85 °C, the transmittance of AgNWs without the AlOx

layer reduced to 79.8% after exposed for 120 h by oxidation of AgNWs. Especially, their transmittance dramatically decreased from exposure for 40 h. However, in the case of AgNWs with the 3

nm-thick AlOx protection layer, the transmittance slightly decreased from 88.1% to 87% after the humidity test at 85 °C for 120 h. Although the transmittance of AgNWs without the AlOx

protection layer dramatically decreased after the humidity test at 85 °C, the transmittance of AgNWs with the AlOx protection layer did not decrease much after humidity and temperature test.

Figure 7(b) shows the resistance change results of AgNWs with and without the AlOx layer after the humidity test at 85 °C. The resistance change of electrodes can be expressed as ΔR = (R −

R0), where R and R0 represent the measured resistance and initial resistance, respectively. The resistance change of AgNWs without the AlOx layer was increased after the humidity test for

120 h. In contrast, AlOx covered AgNWs maintained their initial low resistance without any change after the humidity test at 85 °C. As expected from optical and electrical property results

after humidity and temperature test, we can expect that oxidation of AgNWs leads to deteriorating the optical and electrical properties, and the AlOx layer was isolated well from external

oxygen to AgNWs. Figure 8(a) shows the outer and inner bending test results of AgNWs with and without the AlOx layer. As a result, regardless of the AlOx layer, their resistance is increased

the bending radius of less than 3 mm after the outer bending test. In addition, the resistance of AgNWs with and without the AlOx layer did not change until the inner bending radius of 1

mm. The outer and inner bending reliability test was also performed as shown in Fig. 8(b). AgNWs with and without the AlOx layer exhibited a constant resistance throughout the 10,000 bending

cycles at a fixed bending radius of 3 mm. From these results, we confirm that AgNWs indicate superior mechanical flexibility regardless of the AlOx layer. Figure 8(c) shows cycling bending

steps for the bending test. Finally, we fabricated flexible transparent heaters (120 × 70 mm) using AgNWs with and without the AlOx layer. In the AgNWs without AlOx layer, the temperature

increased only to 40 °C for 40 sec when the input DC voltage was 7 V with a joule heat generation of 0.21 W. However, In case of 3 nm-thick AlOx covered AgNWs, the temperature rapidly

increased to 81 °C within 40 sec when the input DC voltage was 7 V with a joule heat generation of 0.77 W as shown in Fig. 9(a). Also, the temperature of AgNWs with and without AlOx

decreased to room temperature within 40 sec after turn off the DC bias. Figure 9(b) shows the IR images of AgNWs without the AlOx layer (left) and with the AlOx layer (right) under different

deformation modes are taken by an infrared camera while the constant voltage of 7 V was supplied. The heaters using by AlOx covered AgNWs exhibits stable heating performance with uniform

temperature distribution when bent or twisted. Figure 10 shows the on/off response of the flexible heater using by AgNWs with and without the AlOx layer at DC voltage of 7 V. The cycling

curve shows a relatively stable temperature recoverability of the flexible transparent heater. Therefore, this work is expected to be helpful for the development of high performance,

reliable, and flexible transparent conductive film for the fabrication of uniform film heaters. CONCLUSION In this study, we have demonstrated the effects of the AlOx protection layer by the

reactive sputtering method on the electrical, optical, and structural properties of AgNWs prepared by drop-casting and air-dry process. The sheet resistance of the AlOx covered AgNWs

decreased from 81 ohm/sq (without AlOx layer) to 47 ohm/sq (with 3 nm-thick AlOx layer) without transmittance loss. The significantly lower sheet resistance of AgNWs after deposited the AlOx

layer can be attributed to increasing contact area at the junction of AgNWs. Furthermore, the strong networking of AgNWs by covered the AlOx layer lead to the improvement of AgNWs adhesion

to the substrate. We indicate that since the AlOx layer protects AgNWs from external oxygen, the electrical and optical properties of AlOx covered AgNWs did not much change after the high

humidity environment at 85 °C for 120 h. We fabricated a flexible transparent heater with AlOx covered AgNWs. The heater temperature increased to 81 °C within 40 sec at DC voltage of 7 V.

Besides, Fast response and uniform temperature distribution have been achieved. These results strongly suggest that the AlOx covered AgNWs has the potential for the high stability flexible

transparent heater applications. REFERENCES * Pasquier, A. D. _et al_. Conducting and Transparent Single-Wall Carbon Nanotube Electrodes for Polymer-Fullerene Solar Cells. _Appl. Phys.

Lett._ 87(203511), 1–3 (2005). Google Scholar * Aguirre, C. M. _et al_. Carbon Nanotubes as Injection Electrodes for Organic Thin Film Transistors. _Nano Lett._ 9, 1457–1461 (2009). Article

ADS CAS PubMed Google Scholar * Im, K. _et al_. Transparent Heaters Based on Solution-Processed Indium Tin Oxide Nanoparticles. _Thin Solid Films._ 518, 3960–3963 (2010). Article ADS

CAS Google Scholar * Smyth, M. _et al_. Annual Performance of Heat Retaining Integrated Collector/Storage Solar Water Heaters in a Northern Maritime Climate. _Sol. Energy_. 70 (2001).

Article ADS CAS Google Scholar * Yao, S. & Zhu, Y. Nanomaterial-Enabled Stretchable Conductors: Strategies, Materials and Devices. _Adv. Mater._ 27, 1480–1511 (2015). Article CAS

PubMed Google Scholar * Kasimir-Bauer, S. _et al_. Impact of the Expression of P Glycoprotein, the Multidrug Resistance-Related Protein, Bcl-2, Mutant P53, and Heat Shock Protein 27 on

Response to Induction Therapy and Long-Term Survival in Patients with de Novo Acute Myeloid Leukemia. _Exp. Hematol._ 30, 1302–1308 (2002). Article CAS PubMed Google Scholar * Zhang, M.

_et al_. Strong, Transparent Multifunctional, Carbon Nanotube Sheets. _Science_ 309 (August), 1215–1219 (2005). Article ADS CAS PubMed Google Scholar * Bae, S. _et al_. Roll-to-Roll

Production of 30-Inch Graphene Films for Transparent Electrodes. _Nat. Nanotechnol._ 5, 574–578 (2010). Article ADS CAS PubMed Google Scholar * Wang, X. _et al_. Transparent, Conductive

Graphene Electrodes for Dye-Sensitized Solar Cells. _Nano Lett._ 8, 323–327 (2008). Article ADS CAS PubMed Google Scholar * Wu, Z. _et al_. Supporting Information: Transparent,

Conductive Carbon Nanotube Films. _Science_ 305 (August), 1–3 (2004). Article ADS CAS PubMed Google Scholar * Sun, D. M. _et al_. Flexible High-Performance Carbon Nanotube Integrated

Circuits. _Nat. Nanotechnol._ 6, 156–161 (2011). Article ADS CAS PubMed Google Scholar * Vosgueritchian, M. _et al_. Highly Conductive and Transparent PEDOT:PSS Films with a

Fluorosurfactant for Stretchable and Flexible Transparent Electrodes. _Adv. Funct. Mater._ 22, 421–428 (2012). Article CAS Google Scholar * Chou, T. R. _et al_. Highly Conductive

PEDOT:PSS Film by Doping p-Toluenesulfonic Acid and Post-Treatment with Dimethyl Sulfoxide for ITO-Free Polymer Dispersed Liquid Crystal Device. Org. _Electron. physics. Mater Appl._ 48,

223–229 (2017). CAS Google Scholar * Na, S. I. _et al_. Efficient and Flexible ITO-Free Organic Solar Cells Using Highly Conductive Polymer Anodes. _Adv. Mater._ 20, 4061–4067 (2008).

Article CAS Google Scholar * Hwang, J. O. _et al_. Workfunction-Tunable, N-Doped Reduced Graphene Transparent Electrodes for High-Performance Polymer Light-Emitting Diodes. _ACS Nano._ 6,

159–167 (2012). Article CAS PubMed Google Scholar * Cho, H. _et al_. Mechano-thermo-chromic device with supersaturated salt hydrate crystal phase change. _Sci. Adv._ 5, eaav4916 (2019).

Article PubMed PubMed Central Google Scholar * Kim, W. K. _et al_. Cu Mesh for Flexible Transparent Conductive Electrodes. _Sci. Rep._ 5, 1–8 (2015). Google Scholar * Moon, C. J. _et

al_. Flash Light Sintering of Ag Mesh Films for Printed Transparent Conducting Electrode. _Thin Solid Films._ 629, 60–68 (2017). Article ADS CAS Google Scholar * Zhu, X. _et al_.

Fabrication of High-Performance Silver Mesh for Transparent Glass Heaters via Electric-Field-Driven Microscale 3D Printing and UV-Assisted Microtransfer. _Adv. Mater._ 31, 1902479 (2019).

Article CAS Google Scholar * Khan, A. _et al_. High-Performance Flexible Transparent Electrode with an Embedded Metal Mesh Fabricated by Cost-Effective Solution Process. _Small._ 12,

3021–3030 (2016). Article CAS PubMed Google Scholar * Qiu, T. _et al_. Hydrogen Reduced Graphene Oxide/Metal Grid Hybrid Film: Towards High Performance Transparent Conductive Electrode

for Flexible Electrochromic Devices. _Carbon N. Y._ 81, 232–238 (2015). Article CAS Google Scholar * Hecht, D. S. & Kaner, R. B. Solution-Processed Transparent Electrodes. _MRS Bull._

36, 749–755 (2011). Article CAS Google Scholar * Hu, L. _et al_. Scalable Coating and Properties of Transparent, Flexible, Silver Nanowire Electrodes. _ACS Nano._ 4, 2955–2963 (2010).

Article CAS PubMed Google Scholar * Yu, Z. _et al_. Highly Flexible Silver Nanowire Electrodes for Shape-Memory Polymer Light-Emitting Diodes. _Adv. Mater._ 23, 664–668 (2011). Article

CAS PubMed Google Scholar * Yao, S. & Zhu, Y. Wearable Multifunctional Sensors Using Printed Stretchable Conductors Made of Silver Nanowires. _Nanoscale._ 6, 2345–2352 (2014). Article

ADS CAS PubMed Google Scholar * Kim, K. K. _et al_. Highly Sensitive and Stretchable Multidimensional Strain Sensor with Prestrained Anisotropic Metal Nanowire Percolation Networks.

_Nano Lett._ 15, 5240–5247 (2015). Article ADS CAS PubMed Google Scholar * Min, S. –Y. Room-Temperature-Processable Wire-Templated Nanoelectrodes for Flexible and Transparent All-Wire

Electronics. _ACS Nano._ 11, 3681–3689 (2017). Article CAS PubMed Google Scholar * Zhao, S. _et al_. Advancements in Copper Nanowires: Synthesis, Purification, Assemblies, Surface

Modification, and Applications. _Small._ 14, 1800047 (2018). Article CAS Google Scholar * Hong, I. _et al_. Semipermanent Copper Nanowire Network with an Oxidation-Proof Encapsulation

Layer. _Adv. Mater Technol._ 4, 1800422 (2019). Article CAS Google Scholar * Lee, P. _et al_. Highly Stretchable and Highly Conductive Metal Electrode by Vey long Metal Nanowire

Percolation Network. _Adv. Mater._ 24, 3326–3332 (2012). Article CAS PubMed Google Scholar * Lee, J. _et al_. Room-Temperature Nanosoldering of a Very Long Metal Nanowire Network by

Conducting-Polymer-Assisted Joining for a Flexible Touch-Panel Application. _Adv. Funct. Mater._ 23, 4171–4176 (2013). Article CAS Google Scholar * Hong, S. _et al_. Highly Stretchable

and Transparent Metal Nanowire Heater for Wearable Electronics Applications. _Adv. Mater._ 27, 4744–4751 (2015). Article CAS PubMed Google Scholar * Park, K. _et al_. Plasmonic

Nanowire-Enhanced Upconversion Luminescence for Anticounterfeit Devices. _Adv. Funct. Mater._ 26, 7836–7846 (2016). Article CAS Google Scholar * Park, J. H. _et al_. Flash-Induced

Self-Limited Plasmonic Welding of Silver Nanowire Network for Transparent Flexible Energy Harvester. _Adv. Mater._ 29, 1603473 (2017). Article CAS Google Scholar * Choi, S. _et al_.

Highly conductive, stretchable and biocompatible Ag–Au core–sheath nanowire composite for wearable and implantable bioelectronics. _Nature Nanotech._ 13, 1048–1056 (2018). Article ADS CAS

Google Scholar * Kwon, J. _et al_. Recent progress in silver nanowire based flexible/wearable optoelectronics. _J. Mater Chem. C._ 6, 7445–7461 (2018). Article CAS Google Scholar *

Giovanni, M. & Pumera, M. Size Dependant Electrochemical Behavior of Silver Nanoparticles with Sizes of 10, 20, 40, 80 and 107nm. _Electroanalysis._ 24, 615–617 (2012). Article CAS

Google Scholar * Elechiguerra, J. L. _et al_. Corrosion at the Nanoscale: The Case of Silver Nanowires and Nanoparticles. _Chem. Mater._ 17, 6042–6052 (2005). Article CAS Google Scholar

* Azulai, D. _et al_. Metal Nanowire Thin Films Prepared in Mesostructured Templates. _Nano Lett._ 9, 4246–4249 (2009). Article ADS CAS PubMed Google Scholar * Hwang, B. _et al_. Highly

Flexible and Transparent Ag Nanowire Electrode Encapsulated with Ultra-Thin Al2O3: Thermal, Ambient, and Mechanical Stabilities. _Sci. Rep._ 7, 41336 (2017). Article ADS CAS PubMed

PubMed Central Google Scholar * Hong, C.-H. _et al_. Electron Beam Irradiated Silver Nanowires for a Highly Transparent Heater. _Sci. Rep._ 5, 17716 (2015). Article ADS CAS PubMed

PubMed Central Google Scholar * Kwon, J. _et al_. Low-Temperature Oxidation-Free Selective Laser Sintering of Cu Nanoparticle Paste on a Polymer Substrate for the Flexible Touch Panel

Applications. Supporting Information. _ACS Appl. Mater Interfaces._ 8, 11575–11582 (2016). Article CAS PubMed Google Scholar * Cann, M. _et al_. High Performance Transparent Multi-Touch

Sensors Based on Silver Nanowires. _Mater Today Commun._ 7, 42–50 (2016). Article CAS Google Scholar * He, X. _et al_. Screen-Printed Fabrication of PEDOT:PSS/Silver Nanowire Composite

Films for Transparent Heaters. _Materials (Basel)._ 10, 220 (2017). Article ADS PubMed Central CAS Google Scholar * Mutiso, R. M. _et al_. Integrating Simulations and Experiments to

Predict Sheet Resistance and Optical Transmittance in Nanowire Films for Transparent Conductors. _ACS Nano._ 7, 7654–7663 (2013). Article CAS PubMed Google Scholar * Lee, H. J. _et al_.

Effective Indium-Doped Zinc Oxide Buffer Layer on Silver Nanowires for Electrically Highly Stable, Flexible, Transparent, and Conductive Composite Electrodes. _ACS Appl. Mater Interfaces._

5, 10397–10403 (2013). Article CAS PubMed Google Scholar Download references ACKNOWLEDGEMENTS This work was supported by Institute for Information & Communications Technology

Promotion (IITP) grant funded by the Korea government (MSIT, Grant No. 2020-0-00003, Development of high piezoelectric coefficient composite and ultra-low power multilayered piezoelectric

sensor/actuator multi-functional module, and Grant No. 2017-0-00048, Development of Core Technologies for Tactile Input/Output Panels in Skintronics). AUTHOR INFORMATION AUTHORS AND

AFFILIATIONS * Electronics and Telecommunications Research Institute, 218, Gajeong-ro, Yuseong-gu, Daejeon, South Korea Joon-Min Lee, Young-Hoi Kim, Hye-Jin Kim & Chan-Hwa Hong *

University of Science and Technology, 217, Gajeong-ro, Yuseong-gu, Daejeon, South Korea Joon-Min Lee & Hye-Jin Kim * School of Advanced Materials Science & Engineering, Sungkyunkwan

University, Gyeonggi-do, 440-746, South Korea Han-Ki Kim Authors * Joon-Min Lee View author publications You can also search for this author inPubMed Google Scholar * Young-Hoi Kim View

author publications You can also search for this author inPubMed Google Scholar * Han-Ki Kim View author publications You can also search for this author inPubMed Google Scholar * Hye-Jin

Kim View author publications You can also search for this author inPubMed Google Scholar * Chan-Hwa Hong View author publications You can also search for this author inPubMed Google Scholar

CONTRIBUTIONS J.M.L., H.J.K. and C.H.H. conceived and designed the research. J.M.L. and Y.H.K. fabricated thin film devices. J.M.L. and C.H.H. conducted experiments. C.H.H. carried out the

TEM measurements. H.K.K. conducted bending test. J.M.L., H.J.K. and C.H.H. wrote the main manuscript text. All authors discussed the results and reviewed the manuscript. CORRESPONDING

AUTHORS Correspondence to Hye-Jin Kim or Chan-Hwa Hong. ETHICS DECLARATIONS COMPETING INTERESTS The authors declare no competing interests. ADDITIONAL INFORMATION PUBLISHER’S NOTE Springer

Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations. RIGHTS AND PERMISSIONS OPEN ACCESS This article is licensed under a Creative

Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the

original author(s) and the source, provide a link to the Creative Commons license, and indicate if changes were made. The images or other third party material in this article are included in

the article’s Creative Commons license, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons license and your intended

use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this license, visit

http://creativecommons.org/licenses/by/4.0/. Reprints and permissions ABOUT THIS ARTICLE CITE THIS ARTICLE Lee, JM., Kim, YH., Kim, HK. _et al._ Effect of AlOx protection layer on AgNWs for

flexible transparent heater. _Sci Rep_ 10, 4592 (2020). https://doi.org/10.1038/s41598-020-61449-6 Download citation * Received: 07 November 2019 * Accepted: 11 February 2020 * Published: 12

March 2020 * DOI: https://doi.org/10.1038/s41598-020-61449-6 SHARE THIS ARTICLE Anyone you share the following link with will be able to read this content: Get shareable link Sorry, a

shareable link is not currently available for this article. Copy to clipboard Provided by the Springer Nature SharedIt content-sharing initiative