- Select a language for the TTS:

- UK English Female

- UK English Male

- US English Female

- US English Male

- Australian Female

- Australian Male

- Language selected: (auto detect) - EN

Play all audios:

ABSTRACT We present an engineered nanolattice material with enhanced mechanical properties that can be broadly applied as a thin film over large areas. The nanolattice films consist of

ordered, three-dimensional architecture with thin-shell tubular elements, resulting in favorable modulus-density scaling (_n_ ~ 1.1), enhanced energy dissipation, and extremely large

material recoverability for strains up to 20% under normal compressive loading. At 95.6% porosity, the nanolattice film has demonstrated modulus of 1.19 GPa and specific energy dissipation

of 325.5 kJ/kg, surpassing previously reported values at similar densities. The largest length scale in the reported nanolattice is the 500 nm unit-cell lattice constant, allowing the film

to behave more like a continuum material and be visually unobservable. Fabricated using three-dimensional colloidal nanolithography and atomic layer deposition, the process can be scaled for

large-area patterning. The proposed nanolattice film can find applications as a robust multifunctional insulating film that can be applied in integrated photonic elements, optoelectronic

devices, and microcircuit chips. SIMILAR CONTENT BEING VIEWED BY OTHERS CENTIMETRE-SCALE CRACK-FREE SELF-ASSEMBLY FOR ULTRA-HIGH TENSILE STRENGTH METALLIC NANOLATTICES Article 17 June 2021

FULL INTEGRATION OF HIGHLY STRETCHABLE INORGANIC TRANSISTORS AND CIRCUITS WITHIN MOLECULAR-TAILORED ELASTIC SUBSTRATES ON A LARGE SCALE Article Open access 01 April 2024 SOLUTION-PROCESSABLE

ELECTRODE-MATERIAL EMBEDDING IN DYNAMICALLY INSCRIBED NANOPATTERNS (SPEEDIN) FOR CONTINUOUS FABRICATION OF DURABLE FLEXIBLE DEVICES Article Open access 27 September 2021 INTRODUCTION

Naturally occurring cellular materials such as biological exoskeletons1,2,3,4, bones5, cork, and wood6 are lightweight and simultaneously exhibit superior mechanical properties. In these

materials, the composition and architectural arrangement of constituent elements at the micro/nano-scale result in improved stiffness modulus, strength, and energy absorption. Inspired by

biology, engineered cellular materials such as metal foams7, 8, polymer foams9,10,11, and aerogels12,13,14,15,16 have been demonstrated by researchers. Such cellular materials can find

applications in thermal insulation11, 15, 16, acoustic damping15, 16, shock absorption17, 18, as well as in water purification and catalytic reactions16 due to increased surface area.

Similar to the biological examples, many of these materials have micro/nano-scale geometrical constituent elements that are randomly oriented, which are the result of the stochastic nature

of the synthesis and fabrication processes involved. Therefore, while such materials can have extremely low density, it can be difficult to precisely control the architectural arrangements.

It is well known that the mechanical properties of randomly porous cellular material degrade rapidly with lower density. For example, the elastic modulus for cellular solids can be related

to density through the power-law relationship \(E/{E}_{s}\,\alpha \,{{\rho }_{R}}^{n}\), where \({\rho }_{R}\) is relative density, _n_ is scaling factor, and _E_ _s_ and _E_ are elastic

moduli for solid and cellular materials, respectively. For random architectural arrangements the modulus and yield strength scale with a power of _n_ = 3–45, 19,20,21,22. As a result,

materials with random architectures are mechanically less durable at low densities. Recent research in lightweight structures and materials has focused on mitigating the mechanical

degradation for more favorable density scaling. It has been demonstrated that by having an ordered arrangement of constituent elements, mechanical properties of a porous material can be

significantly improved to achieve better density scaling20,21,22,23,24,25,26,27. Such ordered nano/microlattices have resulted in mechanically robust structures with modulus and yield

strength scaling of _n_ = 1–2. The constituent elements can also be made hollow to achieve ultra-low density, while maintaining similar enhanced scaling. In addition, unique architectural

arrangements have shown remarkable material properties such as energy dissipation23, 28,29,30, negative Poisson’s ratio31, ductile-like recoverability22, and high stretchability32. Through

deterministic design of the micro/nanolattice architectures, the material response can be better tailored to achieve optimal mechanical response. While these research present a significant

breakthrough, there are some inherent limitations in the current fabrication approaches. Recent work demonstrating enhanced density scaling of mechanical properties are based on

micro-stereolithography21 and two-photon lithography22, 33, and such techniques have limited spatial resolution and patterning throughput, respectively. Therefore, while the demonstrated

results have nanoscale elements, the lattice is generally larger and ranges from 1–200 μm21, 22, 24, 33, 34. Such materials resemble more like a “structure” rather than a continuous

“material” as a result of the relatively large lattice constant, and can be difficult to integrate for many applications. In addition, while two-photon lithography is an attractive process

due to the ability to create arbitrary 3D patterns, it relies on serial direct-write patterning and can be difficult to apply over a large area in a cost-effective manner. Therefore, while

recent works have demonstrated exciting novel nanomechanics, the nanolattices coverage area are generally limited to 100 × 100 μm2 range and implementation over large area remains a

significant challenge. Here we demonstrate an ordered 3D nanolattice film with enhanced mechanical properties for normal compressive loading using scalable nanofabrication techniques. This

nanolattice film is enabled by 3D colloidal nanolithography, which can be scaled to pattern nanolattice structures over macroscale areas. With lattice constants at least an order of

magnitude smaller than most existing work, this nanolattice behaves as a continuum “material” as opposed to a “structure” and can be widely applied as thin film over any substrate. Having

near sub-wavelength lattice constant, the nanolattice film cannot be observed visually and allows facile integration into a broad range of surfaces and material systems. This 3D nanolattice

film has also demonstrated enhanced mechanical behavior including near-linear modulus scaling with density, and among the highest specific energy dissipation capacity reported for porous

materials. The proposed lightweight nanolattice film also exhibits near-complete material recovery for the thinnest shells (_t_ < 10 nm). In addition to novel mechanical properties, the

nanolattice film has demonstrated refractive index very close to air35. Having over 95% porosity, such highly porous material can also have dielectric constant and thermal conductivity very

close to air, which is often observed in aerogels. Being simultaneously mechanically robust and optically, electrically, and thermally behaving like air, the nanolattice film can find a

potential application as a multifunctional insulating film that can be integrated into multilayer optoelectronic devices, photonic elements, and microcircuits. RESULTS AND DISCUSSION The

fabrication approach is based on the patterning of a periodic 3D photoresist template using colloidal phase lithography36 and atomic layer deposition (ALD), and has been reported

previously35. The pattern size of this technique depends solely on the area of the assembled monodispersed particles, and full-wafer assemblies have been demonstrated37. While local assembly

imperfection, such as point defects and grain boundaries, can exist, the defect area density is generally small (<5%). Samples fabricated for this work were typically ~3 × 3 cm2.

Requiring only a single flood illumination, the exposure time of the 3D lithographic process is on the scale of minutes. The lattice constant of the resist template depends on the particle

diameter, which is typically selected to be around 200–700 nm. While the current work focuses on film with around 1 μm thickness, this fabrication technique has demonstrated thicker films

around 5–10 μm38. This photoresist template can then be conformally coated with thin films of various material compositions using ALD. In this work, Al2O3 and ZnO were selected to fabricate

the nanolattice films due to their attractive bulk properties. The fabrication details used in the experiment is described in Supplementary Information A. It is well-understood that bending

of elements in cellular materials show higher modulus scaling (_n_ ~ 2), resulting in weaker structures at low density. In contrast, the mechanical properties can be enhanced by aligning the

constituent elements along the loading direction, making the elements stretch and compress to allow the scaling to be closer to the theoretical limit (_n_ = 1)18, 20. To achieve near-linear

scaling to compressive and tensile loads normal to the surface, we have designed the nanolattice film to have constituent elements that are vertically aligned and interconnected. This can

be achieved lithographically by using a low exposure wavelength (_λ_ = 325 nm) to particle diameter (_D_ = 500 nm) ratio, which governs the unit-cell geometry38. After removing the

sacrificial polymer template, the resulting structure has a unique arrangement of tubular thin-shell elements, which imparts enhanced mechanical stability to the nanolattice film under

normal compressive loading. This is analogous to micron-scale structural anisotropy obtained through processing in Damascus steel to achieve better properties39. Note that such an

architecture is effective only when the force is normal to the film, and may be weaker along other directions. This lithography configuration was used to fabricate all the samples.

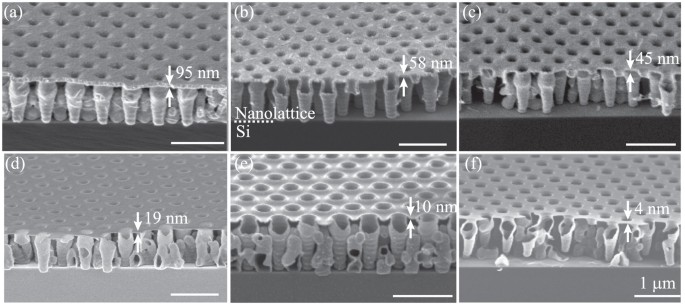

Cross-sectional scanning electron microscope (SEM) images of fabricated 3D nanolattice films are shown in Fig. 1. ZnO nanolattices were fabricated with thicker layers than Al2O3

nanolattices; 95, 45, and 30 nm-thick samples are shown in Fig. 1a–c. ZnO nanolattices with thinner shells were difficult to fabricate, as the polycrystalline ZnO film becomes porous and

collapses during the photoresist template removal process (Supplementary Information B). Al2O3 nanolattice films can be fabricated with thinner shells; 19, 10, and 4 nm-thick samples are

shown Fig. 1d–f. The thinnest Al2O3 sample tested for mechanical properties had a shell thickness of 4 nm. Compared to ZnO, Al2O3 is amorphous, mechanically more resilient and can withstand

the template removal process with a thinner shell thickness. As seen from the cross-sectional SEM images, the architectural arrangement mainly consists of vertically aligned thin-shell

tubular column with secondary interconnecting structures in between. This unique ordered arrangement of thin-shell tubular columns results in enhanced mechanical properties under compressive

loading. For all the samples tested in this study, the lithography parameters were kept constant and the porosity was changed by varying the thickness of the ALD layer. Nanolattice films

with porosities ranging from 60.9–95.6% and 27.2–65.6% for Al2O3 and ZnO, respectively, were tested for mechanical properties. Mechanical properties of both Al2O3 and ZnO nanolattice films

were tested by applying uniaxial compressive loading using nanoindentation. In these experiments a spherical diamond indenter with 10 µm radius was applied with a predefined load on the

nanolattice film. The indenter had a contact area spanning over a few unit cells, which ensures that the applied load predominantly acts normal to the sample surface and the nanolattice film

behaves like a continuum material. To avoid the substrate effect on the measurement of mechanical properties, the maximum nanoindentation depth _h_ was kept close to 10% of the nanolattice

film thickness, which is typically around ~1 μm. Al2O3 and ZnO nanolattice films with varying shell thicknesses were compared for their mechanical properties by calculating the effective

indentation modulus from the slope of unloading curve using the Oliver-Pharr method40. For the nanolattice films tested in this study, a cyclic incremental loading scheme was selected for

nanoindentation characterization (Supplementary Information C). This approach helps to determine indentation modulus prior to ‘pop-in’ events, which signify the first instance of mechanical

failure due to structural collapse either by yielding, buckling, or fracture. A representative nanoindentation incremental cyclic loading-unloading curve for a 30 nm Al2O3 nanolattice with a

‘pop-in’ event noted is shown in Fig. 2a. After the structure collapse at the ‘pop-in’ event, the nanolattice densifies and the architectural arrangement of the structure changes, which

will affect the mechanical properties of the structure during subsequent incremental loading cycles. To avoid this effect, only the cycles before the ‘pop-in’ event were considered for

calculating modulus, hardness, and the energy dissipation. Note this typically occurs when the indentation depth is less than 10% of the film thickness, therefore eliminating any substrate

effects. To get reliable data for mechanical properties, each nanolattice sample was tested at multiple locations. After testing, top-view SEM images were taken for the indented locations to

ensure that the collected data was from a defect-free location (supplementary Information C), and only such data was considered for further calculation of mechanical properties. The SEM

image in Fig. 2a shows the top-view residual indentation on a 30 nm Al2O3 nanolattice sample. The image shows that the sample failed under compressive loading with cracks appearing around

the holes. Cross-sectional images of the residual indent, which might reveal additional failure modes like buckling or rupture of primary tubular shell with increased load after the ‘pop-in’

event, were difficult to obtain since sample cleaving would result in further lattice damage. Similar failure behavior was observed for both Al2O3 and ZnO nanolattice films with shell

thickness larger than 10 nm. Figure 2b,d show the load-displacement curves and post indent SEM images for 15 nm Al2O3 and 45 nm ZnO nanolattice films, respectively. Nanolattice films with

shell thickness smaller than 10 nm had serrated load-displacement curves as shown in Fig. 2c, exhibiting ductile-like behavior. The post indent SEM images do not show fracture on top of the

planar layer and residual indentation imprints. The nanoindentation data were analyzed to calculate the mechanical properties of nanolattice films (Supplementary Information D). The

compressive indentation modulus was calculated by averaging the slope of unloading curves for incremental loading-unloading cycles before the ‘pop-in’ event. This approach reduced the effect

of over predicting of modulus due to densification of nanolattice, and mitigates initial contact error during first loading-unloading cycle. The indentation modulus (_E_) of all

nanolattices was plotted against the density (_ρ_) in Fig. 3, and a near-linear scaling of 1.16 and 1.12 between modulus and density were observed for Al2O3 and ZnO nanolattices,

respectively. This scaling outperforms21, 22 and is comparable34 to previously reported micro/nanolattices with larger lattice parameter >10 μm, demonstrating that enhanced modulus

scaling can also be achieved at the sub-micron lattice regime. The near-linear modulus scaling was the result of the unique nanolattice geometry which has primary thin-shell tubular columns

aligned normal to the surface. The thinnest nanolattice film, constructed from 4 nm-thick Al2O3 with 95.6% porosity, has demonstrated a modulus of 1.19 GPa at density of 127.6 kg/m3. This is

higher than the previously reported value of ~0.5 GPa in literature at similar densities for ordered Al2O3 microlattice21, 22. Furthermore, the modulus achieved for 15 nm thick Al2O3

nanolattice film (_E_ = 6.98 GPa) would require twice the volume fraction in porous Al2O3 aerogel with random architecture41. The non-linear nanoindentation response in the later

loading-unloading cycles results from elastic-plastic deformation of the nanolattice film. During unloading, the elastic work done is released by partial recovery of the nanolattice, but the

plastic work done will be dissipated through localized, permanent deformations of the structure. Figure 4a plots the dissipated energy per weight by Al2O3 and ZnO nanolattices as a function

of relative density before the ‘pop-in’ event. As expected, the thicker structures dissipate higher total energy before collapse. Specific energy dissipation, calculated by normalizing the

total energy by the weight of the solid phase, can be examined to evaluate effectiveness for light-weight applications. For the 4 nm Al2O3 nanolattice sample, the specific energy dissipation

was 325.5 kJ/kg at average indentation lower than 10% (Supplementary Information D), and the total energy absorbed was 1.16 pJ (Table S3). This specific energy dissipation is much larger

than the previously reported polymer foams (0.15 kJ/kg at 21 kg/m3 density), ordered polymer nanoframes (7.67 kJ/kg at 600 kg/m3 density)18, 23, and same order of magnitude as carbon-epoxy

composite nanostructures (720 kJ/kg at 2000 kg/m3)27. In addition, the enhanced energy dissipation by the nanolattice film was also achieved at comparatively smaller total strain and

density. The energy dissipation capacity ranged from 67.2 to 325.5 kJ/kg and 7.54 to 12.07 kJ/kg for Al2O3 and ZnO nanolattices, respectively. The energy dissipation mechanism can be

attributed to brittle fracture of the thin-shell elements within the nanolattice material, which dissipates energy through the creation of micro-cracks (and thus new fracture surfaces).

Under such a mechanism the high surface-area-to-volume ratio plays a critical role, resulting in higher specific energy dissipation for thinner nanolattices. For the thinnest samples with 4

and 6 nm, the material may also exhibit ductile-like properties and contribute to energy absorption. It is important to note that while the specific energy dissipation is high, the total

energy dissipated is in the 1–40 pJ range and is small. Taller nanolattice films are needed to increase the total energy dissipation, and film height of ~10 μm is possible through the

proposed lithography process and can be potentially improved further38. Metallic materials with high ductility can also be used in place of metal oxides to construct the thin-shell

nanolattice, which can further enhance energy dissipation through plastic deformation. In addition to improved modulus and specific energy dissipation, the nanolattice film also exhibits

favorable hardness scaling. The nanolattice hardness was calculated by dividing the load at the ‘pop-in’ event by the indenter contact area at that instance. For the highest porosity sample,

the 4 nm Al2O3 nanolattice had an indentation hardness of 7.8 MPa. The hardness scaling exponents for Al2O3 and ZnO are 1.49 and 1.55 respectively, as shown in Fig. 4b. Similar scaling

exponents for both Al2O3 and ZnO are the result of the unique architectural arrangement of the nanolattice rather than the ALD material property. Failure mode analysis of a simplified

tubular shell element revealed that the two failure modes, fracture and buckling, are governed by critical thickness _t_ _cr_ (Supplementary Information E). The nanolattice undergoes a

fracture-dominated failure mode for film thickness _t_ > _t_ _cr_ where the top planar layer cracks before buckling of tubular columns. For _t_ < _t_ _cr_ , the initial failure in the

nanolattice occurs by buckling of tubular columns, which allows for the film to recover after removing the load. The buckling can be observed in the FEA simulation shown in Supplementary

Information D. The critical thickness is a function of ALD material properties and tubular column geometry; it was calculated to be 11.5 nm for Al2O3 (Supplementary Information E). This

prediction, first reported for nanolattice with larger lattice parameter of 5 μm22, is supported by the nanoindentation results. First, thicker nanolattices governed by fracture-dominated

failure mode have smooth loading-unloading curves but a sharp ‘pop-in’ event, indicating brittle failure of the top planar film. For thinner nanolattices the loading-unloading curve was

serrated and the ‘pop-in’ event was gradual and less pronounced, indicating buckling behavior. Note that fracture can still occur locally within the thinner shell nanolattices to dissipate

energy (indicated in Fig. 4a), since the actual sample geometry is more complex than the simplified analytical shell model. Second, all Al2O3 samples with shell thickness _t_ < _t_ _cr_

had a negative force of indentation when being completely unloaded, as shown for 4 nm Al2O3 nanolattice film in Fig. 2c. This is a result of adhesion force due to van der Waal’s attraction

between the diamond indenter and the recovered nanolattice film (Supplementary Information F). The non-zero adhesion force, even when the nanolattice had regained its original height,

indicates that the nanolattice had fully recovered from compressive loading during indentation. This adhesion force can also be observed for samples with _t_ > _t_ _cr_ during unloading,

but is removed after the tip loses contact with the non-recovered film. Third, the planar top film can be examined post-indent using top-view SEM images to examine indentation footprint. The

recoverability of Al2O3 nanolattice films after complete unloading of the samples is estimated from the indentation plots, and is plotted as a function of relative density in Fig. 4c.

Samples with _t_ > _t_ _cr_ failed by fracture of the top planar layer and show only partial recovery. Whereas, samples with shell thickness _t_ < _t_ _cr_ show ductile-like behavior,

resulting in large recovery after unloading. As predicted by failure mode analysis, thinner nanolattices fail by shell buckling of a primary tubular column and do not result in systematic

collapse. The 4 nm and 6 nm Al2O3 nanolattices show near-complete recovery from compressive strains of about 20%, which corresponds to a total indentation depth of 120 to 180 nm. This can be

confirmed from post indent SEM images (Fig. 2c and Supplementary Information C), which do not display any post indentation residual imprint on the top surface. Note localized structural

damage under the top layer is anticipated and warrants future studies, but the observed damage for _t_ < _t_ _cr_ is not catastrophic and therefore does not deter nanolattice film

recovery. The failure mechanism for nanolattice films depends on ALD material properties, shell thickness and diameter of the tubular column. For all the nanolattice films tested in this

work, the outer diameter of the tubular column was maintained constant to be 252 nm, which resulted in _t_ _cr_ = 11.5 nm for Al2O3 nanolattice films. If the diameter of the tubular column

was reduced further by making lattice constants smaller, _t_ _cr_ would occur at lower shell thickness. Such arrangement will result in stiffer nanolattice films as the structure will be

more difficult to fail by shell buckling. Larger tubular column diameters allow _t_ _cr_ to occur at higher shell thickness, resulting in easier shell buckling under compressive loading.

Such structures are excellent for making recoverable material, but are inherently weaker since they fail at lower stress. The robust nanolattice films fabricated in this work have uniform

lattice period of 500 nm over a large area and cannot be readily observed as they visually resemble a clear film coating. A 10 nm-thick Al2O3 nanolattice film fabricated on glass (“Nano”)

illustrates broadband optical clarity that is similar to the adjacent bare glass slide (“Glass”), as shown in Fig. 5. Note the two samples appear indistinguishable under visual observation.

As the robust transparent nanolattice material can be applied as a thin film over large areas, it can potentially be integrated into multilayer photonic elements to act as an insulating

low-index layer. To improve clarity further, a nanolattice with smaller lattice constants in the 200 nm range is needed and is currently under study. However, this will have to be

accompanied by further thickness reduction in order to achieve the same density. The absolute modulus of the nanolattice film also can be improved further by having more close-packed

arrangement of tubular columns. The high specific energy dissipation of the nanolattice film could be useful in ultra-lightweight energy absorption applications where the load is normal to

the surface. The vertically aligned, interconnected nanolattice material can also be useful in applications involving unidirectional tensile loading. Future work will focus on using thicker

films to enhance total energy absorption. Though the vertically aligned geometry resulted in superior performance for normal loads, this architectural arrangement of nanolattice may be

weaker for loading in the direction in the plane of the film. Such anisotropic response can be examined by using indenter tip with radius of curvature smaller than the lattice constant.

Currently mechanical tests involving shear loading of the nanolattice film to understand the effect of material anisotropy is underway. The effect of structure symmetry on Poisson’s ratio of

the nanolattice film is also of interest and will be analyzed in future work. CONCLUSION In summary, we have demonstrated a new class of mechanically robust 3D nanolattice film which can be

widely applied over any surfaces as a thin film. Under normal compressive loading, the nanolattice film demonstrates near-linear scaling between relative modulus and density, high specific

energy dissipation, and near-complete recoverability from strains of about 20% for the thinnest shell samples. The lattice spacing of 500 nm is the smallest demonstrated to date for

nanolattices, and as a result behaves more as a continuum material and is not visually observable. Using both colloidal 3D nanolithography and ALD, the fabrication process allows precise

control over relative density of the nanolattice and ALD material composition. The highly porous nanolattice film also have refractive index close to air, and can potentially be used as a

multifunctional insulating film that can be applied in integrated photonic elements, optoelectronic devices, and microcircuit chips. METHODS NANOLATTICE THIN-FILM FABRICATION For all the

samples, the silicon substrates were spin-coated with 98 nm of antireflection coating (ARC i-CON-16, Brewer Science, Inc.) to reduce back reflection, and a positive-tone photoresist

(Sumitomo PFi88A7) of ~1 μm thickness. A close-packed monolayer of polystyrene nanospheres with diameter of 500 nm (2.5% Polybead Nonfunctionalized Microspheres, Polysciences, Inc.) was

assembled on the resist and exposure by HeCd laser (_λ_ = 325 nm) to pattern the sacrificial photoresist template. Photoresist 3D templates were subsequently coated with ZnO or Al2O3 using

ALD in a custom made viscous-flow, hot walled, vacuum reactor described previously42,43,44. ALD consists of two, self-limiting half reactions that produce a conformal thin film on samples of

interest. The reactor was purged with high purity nitrogen gas that was further purified with an Entegris GateKeeper. Trimethyl aluminum (TMA, Strem Chemicals, min 98% pure) was used as a

precursor and co-reacted with deionized water to deposit Al2O3. The ALD recipe used for these experiments was 1/30/1/60 (TMA dose/nitrogen purge/water dose/nitrogen purge, in seconds) with a

typical growth rate of 1.1 Å per cycle. The reactor was kept around 550 mTorr at 90 °C. Diethyl zinc (DEZ, Strem Chemicals, min 98% pure) was used as the metal-containing precursor for ZnO.

DEZ/Water ALD cycles were used for ZnO deposition with growth rate of about 1.6 Å per cycle. In both cases, silicon substrates were placed in the front and back of the reactor chamber as

monitors for film growth and film thickness was determined using an α-SE ellipsometer (J. A. Woollam Co., Inc). The polymer template was removed by combinations of thermal treatment using a

furnace (Vulcan 3–130, 100–120 V, DENTSPLY) and/or solvent dissolution using N -Methyl-2-pyrrolidone (NMP). For ZnO samples, the sacrificial photoresist layer was removed by using thermal

treatment alone. For thermal treatments, samples were placed in the furnace at room temperature and the temperature was increased to 550 °C, with a ramp rate of 0.3 °C min−1. The temperature

was maintained at 550 °C for 30 min to ensure that both the photoresist template and the underlying ARC layer were burned off. For Al2O3 nanolattices the photoresist template was first

removed by solvent dissolution method. The samples were placed in NMP for 48 hours to dissolve the photoresist template. Later, the ARC layer was removed using the thermal treatment

described earlier. MECHANICAL TESTING USING NANOINDENTATION Mechanical testing of nanolattice film was carried out by using a CSM Ultra Nanoindentation Tester (UNHT). A spherical diamond

nanoindenter with 20 μm diameter was used for indentation. Initially larger indents with 10000 μN load were made to mark two boundaries of the rectangular indentation region as reference

marks. These two boundaries, 140 μm apart, contained five indents each, marked with 30 μm distance between adjacent indents. Mechanical properties were measured at smaller load using a

cyclic incremental loading approach within the marked area. These smaller indents were made at a predefined distance from the larger indents. This enables identifying the indentation region

for post-indent SEM imaging to ensure data considered for the calculation of mechanical properties was from a defect-free region. For each sample the maximum load applied, initial contact

load and loading rate were kept constant across all indents. The maximum load was selected such that it would result in at least one ‘pop-in’ event during loading. REFERENCES * Meyers, M.

A., Chen, P.-Y., Lopez, M. I., Seki, Y. & Lin, A. Y. M. Biological materials: A materials science approach. _J. Mech. Behav. Biomed. Mater._ 4, 626–657 (2011). Article PubMed Google

Scholar * Meyers, M. A., Chen, P.-Y., Lin, A. Y.-M. & Seki, Y. Biological materials: Structure and mechanical properties. _Prog. Mater. Sci._ 53, 1–206 (2008). Article CAS Google

Scholar * Chen, P.-Y., Lin, A. Y.-M., McKittrick, J. & Meyers, M. A. Structure and mechanical properties of crab exoskeletons. _Acta Biomater._ 4, 587–596 (2008). Article PubMed

Google Scholar * Chen, P.-Y. _et al_. Structure and mechanical properties of selected biological materials. _J. Mech. Behav. Biomed. Mater._ 1, 208–226 (2008). Article PubMed Google

Scholar * Gibson, L. J. Biomechanics of cellular solids. _J. Biomech._ 38, 377–399 (2005). Article PubMed Google Scholar * Ando, K. & Onda, H. Mechanism for deformation of wood as a

honeycomb structure II: First buckling mechanism of cell walls under radial compression using the generalized cell model. _J. Wood Sci._ 45, 250–253 (1999). Article Google Scholar *

Tappan, B. C. _et al_. Ultralow-Density Nanostructured Metal Foams: Combustion Synthesis, Morphology, and Composition. _J. Am. Chem. Soc._ 128, 6589–6594 (2006). Article CAS PubMed

Google Scholar * Verdooren, A., Chan, H. M., Grenestedt, J. L., Harmer, M. P. & Caram, H. S. Fabrication of Low-Density Ferrous Metallic Foams by Reduction of Chemically Bonded Ceramic

Foams. _J. Am. Ceram. Soc._ 89, 3101–3106 (2006). Article CAS Google Scholar * Chanda, M. & Roy, S. K. _Plastics Technology Handbook_, _Fourth Edition_. (CRC Press, 2006). * Lee, L.

J. _et al_. Polymer nanocomposite foams. _Compos. Sci. Technol._ 65, 2344–2363 (2005). Article CAS Google Scholar * Liu, S., Duvigneau, J. & Vancso, G. J. Nanocellular polymer foams

as promising high performance thermal insulation materials. _Eur. Polym. J._ 65, 33–45 (2015). Article CAS Google Scholar * Tillotson, T. M. & Hrubesh, L. W. Transparent

ultralow-density silica aerogels prepared by a two-step sol-gel process. _J. Non-Cryst. Solids_ 145, 44–50 (1992). Article ADS CAS Google Scholar * Zou, J. _et al_. Ultralight

Multiwalled Carbon Nanotube Aerogel. _ACS Nano_ 4, 7293–7302 (2010). Article CAS PubMed Google Scholar * Nyström, G., Fernández-Ronco, M. P., Bolisetty, S., Mazzotti, M. & Mezzenga,

R. Amyloid Templated Gold Aerogels. _Adv. Mater_. n/a–n/a doi:10.1002/adma.201503465 (2015). * Hüsing, N. & Schubert, U. Aerogels—Airy Materials: Chemistry, Structure, and Properties.

_Angew. Chem. Int. Ed._ 37, 22–45 (1998). Article Google Scholar * Pierre, A. C. & Pajonk, G. M. Chemistry of Aerogels and Their Applications. _Chem. Rev._ 102, 4243–4266 (2002).

Article CAS PubMed Google Scholar * _Materials Selection in Mechanical Design, Fourth Edition_. (Butterworth-Heinemann, 2010). * _Cellular Solids: Structure and Properties_. (Cambridge

University Press, 1999). * Ma, H.-S., Prévost, J.-H., Jullien, R. & Scherer, G. W. Computer simulation of mechanical structure–property relationship of aerogels. _J. Non-Cryst. Solids_

285, 216–221 (2001). Article ADS CAS Google Scholar * Schaedler, T. A. _et al_. Ultralight Metallic Microlattices. _Science_ 334, 962–965 (2011). Article ADS CAS PubMed Google

Scholar * Zheng, X. _et al_. Ultralight, ultrastiff mechanical metamaterials. _Science_ 344, 1373–1377 (2014). Article ADS CAS PubMed Google Scholar * Meza, L. R., Das, S. & Greer,

J. R. Strong, lightweight, and recoverable three-dimensional ceramic nanolattices. _Science_ 345, 1322–1326 (2014). Article ADS CAS PubMed Google Scholar * Lee, J.-H., Wang, L., Kooi,

S., Boyce, M. C. & Thomas, E. L. Enhanced Energy Dissipation in Periodic Epoxy Nanoframes. _Nano Lett._ 10, 2592–2597 (2010). Article ADS CAS PubMed Google Scholar * Jang, D., Meza,

L. R., Greer, F. & Greer, J. R. Fabrication and deformation of three-dimensional hollow ceramic nanostructures. _Nat. Mater._ 12, 893–898 (2013). Article ADS CAS PubMed Google

Scholar * Bauer, J., Hengsbach, S., Tesari, I., Schwaiger, R. & Kraft, O. High-strength cellular ceramic composites with 3D microarchitecture. _Proc. Natl. Acad. Sci._ 111, 2453–2458

(2014). Article ADS CAS PubMed PubMed Central Google Scholar * Schaedler, T. A. _et al_. Designing Metallic Microlattices for Energy Absorber Applications. _Adv. Eng. Mater._ 16,

276–283 (2014). Article CAS Google Scholar * Zheng, X. _et al_. Multiscale metallic metamaterials. _Nat. Mater._ 15, 1100–1106 (2016). Article ADS CAS PubMed Google Scholar * Lee,

J.-H., Wang, L., Boyce, M. C. & Thomas, E. L. Periodic Bicontinuous Composites for High Specific Energy Absorption. _Nano Lett._ 12, 4392–4396 (2012). Article ADS CAS PubMed Google

Scholar * Zhang, Q. _et al_. Energy-Absorbing Hybrid Composites Based on Alternate Carbon-Nanotube and Inorganic Layers. _Adv. Mater._ 21, 2876–2880 (2009). Article CAS Google Scholar *

Wang, L., Boyce, M. C., Wen, C.-Y. & Thomas, E. L. Plastic Dissipation Mechanisms in Periodic Microframe-Structured Polymers. _Adv. Funct. Mater._ 19, 1343–1350 (2009). Article CAS

Google Scholar * Greaves, G. N., Greer, A. L., Lakes, R. S. & Rouxel, T. Poisson’s ratio and modern materials. _Nat. Mater._ 10, 823–837 (2011). Article ADS CAS PubMed Google

Scholar * Bagal, A. _et al_. Multifunctional nano-accordion structures for stretchable transparent conductors. _Mater. Horiz._ 2, 486–494 (2015). Article CAS Google Scholar * Bauer, J.,

Schroer, A., Schwaiger, R. & Kraft, O. Approaching theoretical strength in glassy carbon nanolattices. _Nat. Mater._ 15, 438–443 (2016). Article ADS CAS PubMed Google Scholar *

Meza, L. R. _et al_. Resilient 3D hierarchical architected metamaterials. _Proc. Natl. Acad. Sci._ 2015, 09120, doi:10.1073/pnas.1509120112 (2015). Google Scholar * Zhang, X. A. _et al_.

Ordered 3D Thin-Shell Nanolattice Materials with Near-Unity Refractive Indices. _Adv. Funct. Mater._ 25, 6644–6649 (2015). Article CAS Google Scholar * Chang, C.-H. _et al_. From

Two-Dimensional Colloidal Self-Assembly to Three-Dimensional Nanolithography. _Nano Lett._ 11, 2533–2537 (2011). Article ADS CAS PubMed Google Scholar * Jiang, P. & McFarland, M. J.

Large-Scale Fabrication of Wafer-Size Colloidal Crystals, Macroporous Polymers and Nanocomposites by Spin-Coating. _J. Am. Chem. Soc._ 126, 13778–13786 (2004). Article CAS PubMed Google

Scholar * Min, J.-H., Zhang, X. A. & Chang, C.-H. Designing unit cell in three-dimensional periodic nanostructures using colloidal lithography. _Opt. Express_ 24, A276 (2016). Article

CAS PubMed Google Scholar * Sherby, O. D. & Wadsworth, J. Ancient blacksmiths, the Iron Age, Damascus steels, and modern metallurgy. _J. Mater. Process. Technol._ 117, 347–353 (2001).

Article CAS Google Scholar * Oliver, W. c. & Pharr, G. m. An improved technique for determining hardness and elastic modulus using load and displacement sensing indentation

experiments. _J. Mater. Res._ 7, 1564–1583 (1992). Article ADS CAS Google Scholar * Yokokawa, R. _et al_. Mechanical properties of aerogel-like thin films used for MEMS. _J.

Micromechanics Microengineering_ 14, 681 (2004). Article ADS Google Scholar * Gong, B. _et al_. Sequential Vapor Infiltration of Metal Oxides into Sacrificial Polyester Fibers: Shape

Replication and Controlled Porosity of Microporous/Mesoporous Oxide Monoliths. _Chem. Mater._ 23, 3476–3485 (2011). Article CAS Google Scholar * Spagnola, J. C. _et al_. Surface and

sub-surface reactions during low temperature aluminium oxide atomic layer deposition on fiber-forming polymers. _J. Mater. Chem._ 20, 4213–4222 (2010). Article CAS Google Scholar * Jur,

J. S. _et al_. Temperature-Dependent Subsurface Growth during Atomic Layer Deposition on Polypropylene and Cellulose Fibers. _Langmuir_ 26, 8239–8244 (2010). Article CAS PubMed Google

Scholar Download references ACKNOWLEDGEMENTS This work was performed in part at the NCSU Nanofabrication Facility (NNF) and the Analytical Instrumentation Facility (AIF) at North Carolina

State University, which are supported by the State of North Carolina and the National Science Foundation (award number ECCS-1542015). The NNF and AIF are members of the North Carolina

Research Triangle Nanotechnology Network (RTNN), a site in the National Nanotechnology Coordinated Infrastructure (NNCI). This work was supported by NSF Faculty Early Career Development

(CAREER) Program (grant CMMI#1552424) and NASA Office of the Chief Technologist’s Space Technology Research Opportunity – Early Career Faculty grant (grant NNX12AQ46G). AUTHOR INFORMATION

AUTHORS AND AFFILIATIONS * Department of Mechanical and Aerospace Engineering, North Carolina State University, Raleigh, North Carolina, 27695, United States Abhijeet Bagal, Xu A. Zhang,

Felipe R. Poblete, Yong Zhu & Chih-Hao Chang * Department of Civil, Construction and Environmental Engineering, North Carolina State University, Raleigh, NC, 27695, United States Rahnuma

Shahrin & Christopher Bobko * Department of Chemical and Bimolecular Engineering, North Carolina State University, Raleigh, North Carolina, 27695, United States Erinn C. Dandley, Junjie

Zhao, Christopher J. Oldham & Gregory N. Parsons Authors * Abhijeet Bagal View author publications You can also search for this author inPubMed Google Scholar * Xu A. Zhang View author

publications You can also search for this author inPubMed Google Scholar * Rahnuma Shahrin View author publications You can also search for this author inPubMed Google Scholar * Erinn C.

Dandley View author publications You can also search for this author inPubMed Google Scholar * Junjie Zhao View author publications You can also search for this author inPubMed Google

Scholar * Felipe R. Poblete View author publications You can also search for this author inPubMed Google Scholar * Christopher J. Oldham View author publications You can also search for this

author inPubMed Google Scholar * Yong Zhu View author publications You can also search for this author inPubMed Google Scholar * Gregory N. Parsons View author publications You can also

search for this author inPubMed Google Scholar * Christopher Bobko View author publications You can also search for this author inPubMed Google Scholar * Chih-Hao Chang View author

publications You can also search for this author inPubMed Google Scholar CONTRIBUTIONS A.B. fabricated the samples, performed characterization experiments, mechanical modeling, and data

analysis. X.Z. helped in development of the fabrication process and sample preparation. E.D., J.Z. and C.O. developed ALD process. F.P. and Y.Z. helped with FEA simulation and analysis. R.S.

helped in nanoindentation experiments. C.B. supervised nanoindentation experiments and data analysis. C.-H.C., C.B. and G.P. proposed and supervised the project. All authors participated in

the discussions of the research and contributed to the manuscript. CORRESPONDING AUTHOR Correspondence to Chih-Hao Chang. ETHICS DECLARATIONS COMPETING INTERESTS The authors declare that

they have no competing interests. ADDITIONAL INFORMATION PUBLISHER'S NOTE: Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional

affiliations. ELECTRONIC SUPPLEMENTARY MATERIAL SUPPLEMENTARY INFORMATION ALUMINA NANOLATTICE 10 NM ALUMINA NANOLATTICE 40 NM RIGHTS AND PERMISSIONS OPEN ACCESS This article is licensed

under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate

credit to the original author(s) and the source, provide a link to the Creative Commons license, and indicate if changes were made. The images or other third party material in this article

are included in the article’s Creative Commons license, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons license and

your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this

license, visit http://creativecommons.org/licenses/by/4.0/. Reprints and permissions ABOUT THIS ARTICLE CITE THIS ARTICLE Bagal, A., Zhang, X.A., Shahrin, R. _et al._ Large-Area Nanolattice

Film with Enhanced Modulus, Hardness, and Energy Dissipation. _Sci Rep_ 7, 9145 (2017). https://doi.org/10.1038/s41598-017-09521-6 Download citation * Received: 31 May 2017 * Accepted: 17

July 2017 * Published: 22 August 2017 * DOI: https://doi.org/10.1038/s41598-017-09521-6 SHARE THIS ARTICLE Anyone you share the following link with will be able to read this content: Get

shareable link Sorry, a shareable link is not currently available for this article. Copy to clipboard Provided by the Springer Nature SharedIt content-sharing initiative

:max_bytes(150000):strip_icc():focal(319x0:321x2)/people_social_image-60e0c8af9eb14624a5b55f2c29dbe25b.png)