- Select a language for the TTS:

- UK English Female

- UK English Male

- US English Female

- US English Male

- Australian Female

- Australian Male

- Language selected: (auto detect) - EN

Play all audios:

ABSTRACT Ti3C2T_x_ MXene is an emerging class of two-dimensional nanomaterials with exceptional electroconductivity and electrochemical properties, and is promising in the manufacturing of

multifunctional macroscopic materials and nanomaterials. Herein, we develop a straightforward, continuously controlled, additive/binder-free method to fabricate pure MXene fibers via a

large-scale wet-spinning assembly. Our MXene sheets (with an average lateral size of 5.11 μm2) are highly concentrated in water and do not form aggregates or undergo phase separation.

Introducing ammonium ions during the coagulation process successfully assembles MXene sheets into flexible, meter-long fibers with very high electrical conductivity (7,713 S cm−1). The

fabricated MXene fibers are comprehensively integrated by using them in electrical wires to switch on a light-emitting diode light and transmit electrical signals to earphones to demonstrate

their application in electrical devices. Our wet-spinning strategy provides an approach for continuous mass production of MXene fibers for high-performance, next-generation, and wearable

electronic devices. SIMILAR CONTENT BEING VIEWED BY OTHERS ULTRA-COMPACT MXENE FIBERS BY CONTINUOUS AND CONTROLLABLE SYNERGY OF INTERFACIAL INTERACTIONS AND THERMAL DRAWING-INDUCED STRESSES

Article Open access 05 August 2022 CONDUCTANCE STABLE AND MECHANICALLY DURABLE BI-LAYER EGAIN COMPOSITE-COATED STRETCHABLE FIBER FOR 1D BIOELECTRONICS Article Open access 13 July 2023

ULTRASTRONG MXENE FILMS VIA THE SYNERGY OF INTERCALATING SMALL FLAKES AND INTERFACIAL BRIDGING Article Open access 29 November 2022 INTRODUCTION Two-dimensional (2D) nanosheets with

fascinating properties are building blocks for potential applications1,2. Compared with their bulk counterparts, 2D nanomaterials are easy-to-assemble structures for nanoscale architectures

that have appealing electronic, chemical, physical, and mechanical properties; a high specific surface area; and versatile surface chemistries3,4,5. To date, various 2D materials, such as

graphene, hexagonal boron nitride (h-BN), graphitic carbon nitride (g-C3N4), transition metal dichalcogenides (TMDs), black phosphorus (BP), and transition metal oxides (TMOs), have garnered

considerable attention, and many strategies have been proposed to develop them into macroscopic structures6,7,8,9,10. For example, significant advancements have been made regarding the

development of macroscopic one-dimensional (1D) carbon-based fibers prepared from graphene oxides (GO)11. Graphene-related fibers have gained considerable interest because of their versatile

functionalities, such as lightweight, mechanical flexibility, bendability, stretchability, and the ability to be woven into textiles for the next generation of smart electronic

gadgets12,13. In particular, to realize the macroscopic assembly of 2D nanosheets into fiber structures, the wet-spinning process, which utilizes the phase change ability of highly

concentrated colloidal dispersions (i.e., \ in the liquid state) to transform into gel-fiber assemblies and solid fibers in a coagulation bath, has been demonstrated as a versatile pathway

for the long and continuous mass production of fibers11,14. Notably, understanding the molecular interaction between sheets and systematic studies on the parameters of the coagulation

process are crucial to achieving fiber formation from individual colloidal particles. Ti3C2T_x_ MXene is composed of transition metal nitrides and carbides (MXenes) and has been extensively

explored as an emerging family of 2D materials because of its excellent electrical–thermal conductivity, mechanical, and chemical properties, and wide range of potential

applications15,16,17,18,19. MXenes have the general configuration of _M__n_+1_X__n__T__x_, in which _M_, _X_, and _T_ represent transition metals, carbon/nitrogen, and surface terminal

functionalities, such as O, F, and OH, respectively. MXenes are typically obtained as sheet materials with a nanoscale thickness via the delamination of the _MAX_ (_M__n_+1_AX__n_) phase16.

Very recently, several researchers have attempted to fabricate MXene-based fibers using wet-spinning and electrospinning with MXene/polymer blend dope solutions and MXene/rGO for

coassembly20,21. However, the intrinsically high electrical conductivity of pure Ti3C2T_x_ MXene (up to 9880 S cm−1 for spray-cast films) is lower than that of MXene composites with reduced

GO (rGO) (72–290 S cm−1)21,22, CNT fiber (26 S cm−1)23, and PEDOT:PSS (1489 S cm−1)24, showing that the conductivity of MXenes is not fully utilized in the fiber form. The crucial challenge

regarding wet-spinning for pure MXene fibers is the weak self-supporting organization because of poor interlayer interaction between the relatively small MXene sheets. In addition, a low

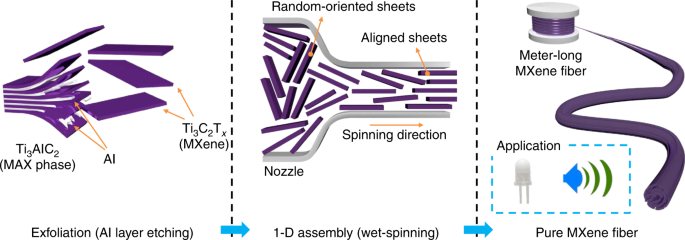

concentration of dispersion has made it challenging to process MXene directly into a 1D fiber form. Herein, we report a straightforward and reliable synthetic route for continuously

controlled fabrication of additive/binder-free, composite-free, entirely pure 1D MXene fibers with high electrical conductivity by a wet-spinning assembly (Fig. 1). The dispersion with a

relatively large Ti3C2T_x_ MXene sheet (the average size and aspect ratio were ~5.11 μm2 and 1600, respectively) at a high concentration (25 mg mL−1) demonstrated highly stable colloidal

properties in a lyotropic liquid-crystalline phase. The wet-spinning of the 2D MXene spinning dope successfully produced flexible meter-long continuous MXene fibers with an ultrahigh

electrical conductivity of 7713 S cm−1. The MXene fibers that exhibited excellent performance were used for the electrical wires to switch on an LED light and wires to transmit electrical

signals to earphones. Furthermore, the MXene fibers showed high flexibility and excellent mechanical properties. The wet-spinning strategy reported in this work suggests a method for the

continuous mass production of MXene fibers, which indicates that they are promising candidates for high-performance, flexible, portable, and wearable electronics. The development of

nanoscale properties on the macroscopic level using a scalable assembly represents progress toward the practical application of these extraordinary 2D materials. RESULTS SYNTHESIS AND

CHARACTERIZATION OF TI3C2T_X_ MXENE SHEETS A MAX-phase (Ti3AlC2) powder with graphite-like stacked-layer structures was observed in images obtained via scanning electron microscopy (SEM)

(Fig. 2a and Supplementary Fig. 1a). MXene (Ti3C2T_x_) sheets were obtained by selectively etching the Al from a Ti3AlC2 powder using LiF and HCl, as reported previously25. SEM images of

fully exfoliated MXene monolayers showed an average lateral size of 2.26 ± 0.95 μm (Fig. 2b and Supplementary Fig. 1b, c). The height profile obtained via atomic force microscopy (AFM)

mapping revealed that the MXene sheets had a height of 1.35–1.81 nm, which corresponded to a single layer of the MXene, implying the successful exfoliation of the sheets (Supplementary Fig.

1d and e)26. The folded MXene was identified as a double layer according to the AFM height profile, which showed a height of 3.31–3.72 nm; this agrees with the results of previous reports26.

Conductive atomic force microscopy (C-AFM) clearly showed that the MXene sheets were very electrically conductive (Fig. 2d, e). The prepared MXene monolayer was also observed using

transmission electron microscopy (TEM), and highly crystalline lattice fringes with a lattice spacing of 0.26 nm corresponding to the Ti3C2T_x_ (100) plane were clearly observed in the

HR-TEM images. The selected area electron diffraction (SAED) pattern confirmed that the MXene sheets had a typical hexagonal symmetry (Supplementary Fig. 2a and b). The XRD pattern and the

atomic percent of MXene confirmed the complete etching of the Al layer (Supplementary Fig. 2c and Supplementary Table 1)27. The corresponding elemental maps confirmed the uniform

distribution of all elements, suggesting that the surface of the MXene sheet contained oxygen and fluorine as termination groups (Supplementary Fig. 2d). The chemical functionalities of the

exfoliated MXene sheets were further examined via X-ray photoelectron spectroscopy (XPS). The deconvoluted C1_s_, O1_s_, and Ti2_p_ XPS peaks demonstrated that inherent termination groups,

such as C–Ti–T_x_, C–Ti–(OH)_x_, and C–Ti–O_x_, existed on the surface of the MXene and were likely introduced during the Al etching of the MAX crystals (Fig. 3a, b, Supplementary Fig.

2a–c). Notably, these surface functionalities are important for the formation of a stable dispersion in an aqueous medium28. The negative surface charge values increased with the pH of

MXene, owing to the ionizable surface termination groups, suggesting strong electrostatic repulsion between the adjacent sheets (Fig. 3c)29,30. The apparent dispersibility of the MXene was

observed at various concentration ranges (Fig. 3d), and no sediment was formed on the bottom of the vials at different MXene concentrations. The absorbance of the MXene dispersion was

examined, as shown in Supplementary Fig. 3d. In the inset of Supplementary Fig. 3d, a linear relationship between the UV absorbance and concentration of MXene sheets was observed, confirming

the stability of the dispersed state31. RHEOLOGICAL PROPERTIES OF MXENE INK At a high concentration (25 mg mL−1), the MXene dispersion formed a viscous ink with a viscosity of 3.87 × 103 Pa

s and without aggregates and phase separation of solid particles and dispersing media (Fig. 3e)28,32. Based on Onsager’s theoretical prediction model, MXene sheets can exhibit lyotropic

liquid-crystalline properties from ~16 mg mL−1 33. As shown in Fig. 3f, the MXene dispersion (25 mg mL−1) also exhibited birefringence between two crossed polarizers, indicating the

formation of a liquid-crystalline phase as a result of local orientation that did not aggregate. As is often observed in complex fluid systems containing rigid polymer chains, the viscosity

of the MXene increased with the concentration and decreased with an increase in the shear rate (Fig. 3g)34,35,36. Furthermore, the shear stress of the MXene dispersion significantly

decreased at the initial stage and then gradually increased with the shear rate (Fig. 3h), suggesting that the randomly oriented MXene sheets became arranged as a result of the shear-induced

deformation10. A decrease in the shear stress was clear in concentrated dispersions (higher than 15 mg mL−1). Notably, the ratio of the storage modulus to the loss modulus (_G_′/_G_″) of a

dispersion can be used as an indicator for the spinnability of liquid-crystalline 2D colloidal dispersions37. Wallace et al. reported that the wet-spinning of GO dispersions is achievable

when the value of _G_′/_G_″ is between 1.80 and 6.36 at an angular rate of 0.02 Hz. Gogotsi et al. also expected that highly concentrated MXene dispersions can be wet-spun into fibers by

following this relation35. Similarly, we found that the spinnability of an MXene dispersion could be predicted using the _G_′/_G_″ value of the MXene. Experimentally, at 5 mg mL−1, the MXene

dispersion herein was not capable of forming fibers because of the weak gel strength, and the value of _G_′/_G_″ was 13.33 (Supplementary Fig. 4). When the _G_′/_G_″ value of the MXene was

6.64 at 12 mg mL−1, the fiber was not stably formed herein, but MXene dispersions with over 15 mg mL−1 (the _G_′/_G_″ value was 5.29 at 15 mg mL−1) were successfully fabricated into MXene

fibers (Fig. 3i). WET-SPINNING OF PURE MXENE FIBERS Note that the colloidal stability of MXene sheets can be considerably affected by salts. The role of NH4 ions in the gelation of MXene

dispersions was confirmed by the vial inversion method (Fig. 4a)14. Indeed, similar to the behavior of graphene and other 2D materials, the high degree of exfoliation/delamination and

gelation of MXenes is essential for continuous fiber fabrication. The prepared MXene liquid crystal dispersion was extruded into a coagulation solution with NH4 ions and then washed in a

water bath through a reel to produce continuous fibers using a simple wet-spinning method (Fig. 4b and Supplementary video). The extruded MXene did not form gel fibers without NH4 ions

(Supplementary Fig. 5). Finally, the fibers were dried in air for 24 h and formed uniform, long, continuous MXene fibers oriented in the axial direction. The meter-long MXene fibers produced

on a large scale by continuous spinning were wound onto a bobbin (Fig. 4c). The extruded 100% pure MXene fibers that were longer than 1 m were stable with continuous spinning (Fig. 4d). The

cross-section of the MXene fibers showed a lamellar structure with highly compact nanosheets (Fig. 4e–g). The rugged morphology on the side of the fibers indicated that drying and shrinking

occurred (Fig. 4g). Highly conducting MXene fibers were used for an electrical application that involved successfully switching on a white light-emitting diode (LED) light (Fig. 4h).

Furthermore, the MXene fibers replaced commercially used wires and were integrated into earphone wires to transmit electrical signals (Fig. 4i, Supplementary audio). PERFORMANCES OF MXENE

FIBER Figure 5 compares the electrical conductivity and Young’s modulus of our fabricated MXene fibers with those of MXene hybrid fibers and graphene fibers fabricated in previous studies

(Supplementary Fig. 6 and Supplementary Table 2)21,22,23,24,38,39,40,41,42,43,44,45. From the Ashby plot, it is clear that our wet-spun pure MXene fibers are superior to the other considered

fibers in terms of electrical conductivity and Young’s modulus. The electrical conductivity of the MXene fibers (7713 S cm−1) was almost 107 and 27 times higher than that of MXene/graphene

hybrid fibers (72.3 and 290 S cm−1, respectively)21,22 and five times higher than that of MXene/PEDOT:PSS fibers (1490 S cm−1)24, which were reported previously. Furthermore, the

conductivity of the MXene fibers in this work was ~12–220 times higher than that of the graphene fibers38,39,40,41,42,43,44. In addition, the pure MXene fibers were 3.2 times more conductive

than reported MXene films at the macroscopic scale, implying that the MXene fibers had a well-constructed structure45. DISCUSSION We effectively developed pure Ti3C2T_x_ MXene fibers that

were free of additives/binders or composites via a straightforward, continuous, large-scale, wet-spinning strategy. The large Ti3C2T_x_ MXene sheets had an excellent dispersion at a high

concentration of 25 mg mL−1 and demonstrated liquid-crystalline patterns and rheological properties of lyotropic liquid crystals. The Ti3C2T_x_ MXene fibers fabricated by a wet-spinning

method herein exhibited a very high electrical conductivity of 7713 S cm−1, and flexible, continuous, meter-long MXene fibers were successfully fabricated. Considering these outstanding

properties, we comprehensively integrated the Ti3C2T_x_ MXene fibers in electrical wires for switching on an LED light and transmitting electrical signals to earphones to demonstrate the

application of the fibers in miniaturized portable devices. Therefore, we believe that our wet-spinning strategy for continuous mass production of pure Ti3C2T_x_ MXene fibers offers a way to

exploit the original nanoscale potential of MXenes at the macroscopic scale. In addition, the approach herein advances the use of a large family of MXenes in next-generation flexible,

portable, and wearable miniaturized electronic devices. METHODS MATERIALS The layered ternary carbide (Ti3AlC2) MAX-phase powders were purchased from Carbon-Ukraine Ltd. (particle size <

200 μm, Ukraine). The chemicals, including hydrochloric acid (HCl), lithium fluoride (LiF), ammonium chloride (NH4Cl), and ammonium hydroxide (NH4OH), were purchased from Sigma-Aldrich Co

(St. Louis, MO, USA). Deionized water (DIW) was obtained using a water-purification system (Direct Q3) purchased from Millipore (Bedford, MA, USA). SYNTHESIS OF THE TI3C2T_X_ MXENE The

Ti3C2T_x_ MXene was obtained from Ti3AlC2 precursors by modifying a previously reported method25. A quantity of 2 g of LiF was dissolved into 40 mL of a 9 M HCl solution in a reactor. The

solution was stirred for 30 min at 35 °C. After slowly adding 2 g of the Ti3AlC2 (MAX phase) powder, the mixture was stirred in an argon atmosphere for 24 h. The Al layer in the MAX phase

was etched to exfoliate the Ti3C2T_x_. Then, 40 mL of the obtained solution was divided into 20 mL conical tubes and diluted with water (20 mL). To separate the MXene dispersion from the

acid, it was washed with water using a centrifuge until the pH reached 6. As the pH of the solution was almost neutral, the MXene in the dispersion did not sink well through centrifugation

due to an increase in the negative zeta potential of their surface. The washed solution (pH 6) was centrifuged repeatedly to purify the MXene sheets and to concentrate the MXene dispersion.

The obtained solution was sealed with parafilm and stored at ~5 °C. WET-SPINNING OF THE PURE TI3C2T_X_ (ALL-MXENE) FIBERS The MXene dispersion was placed in a syringe and extruded through

the nozzle (diameter = 210 μm) into the prepared coagulant. The coagulate solution was a mixture of NH4Cl (50 g), NH4OH solution (20 mL), and DIW (1000 mL). The MXene dispersions were

extruded at a velocity of 7 mL h−1. The extruded MXene fibers in the coagulate solution were transferred to a washing bath by rollers. The washed fibers were dried in air and then stored in

a dry chamber. CHARACTERIZATION The concentration of the concentrated dispersion was defined by cross-validation with the Beer–Lambert Law using UV–vis spectroscopy (Lambda 650S, Perkin

Elmer, USA) and directly measuring the mass of the powder per unit volume of dispersion using an ultra-micro balance (XPR2U, Mettler-Toledo GmbH, Greifensee, Switzerland). The dimensions of

the MXene sheets and the morphologies of the MXene fibers were characterized using SEM (S4800, Hitachi, Japan) at 15 kV and 10 μA without Pt sputtering. The topography of the MXene sheets

was observed via AFM (XE-70, Park Systems, Korea) in tapping mode. The measured data were processed using a data processing and analysis software (XEI, Park Systems). The topography and a

current image of the MXene nanosheets on the Si wafers were obtained simultaneously during the C-AFM scan. In this study, we conducted current measurements on the in-plane surface, which was

consistent with the direction of the carrier transport parameter measurements. A cantilever (CDT-CONTR, Park systems) was used, and the measurement was performed with a fixed bias of 10 V.

The cantilever had a resonance frequency of ~20 kHz, a spring constant of 0.5 N m−1, and a tip radius between 100 and 200 nm. All measurements were performed at room temperature (~25 °C) and

in ambient conditions. The synthesized MXene single layer was characterized using HR-TEM (JEM-2100F, JEOL, Japan). The terminal group and the chemical state of the MXene were analyzed via

XPS (Theta probe, Thermo Scientific, UK) with monochromatic Al Kα radiation. The XPS spectra were analyzed using Xpspeak41 software. The rheological properties of the MXene dispersion were

measured using a rheometer (MCR 501, Anton Paar, Austria) under both steady shear and dynamic oscillatory conditions. The viscoelastic properties of the Ti3C2T_x_ dispersion were

investigated by measuring the storage and loss modulus as a function of frequency from 0.1 to 1000 rad/s. During the frequency sweep, the strain amplitude was maintained at 0.1% (a gap of 1

mm, 25 °C)35. An optical image of the meter-long MXene fibers with a ruler was obtained by joining several close-up images taken vertically from above the fibers because the fibers were too

thin for an image to be obtained from far away. The tensile properties of the MXene fibers prepared from different concentrations of dispersion were investigated using a universal testing

machine (5966, Instron, USA) equipped with a 10 N load cell that operated at a crosshead speed of 2.5 mm min−1 and had a gauge length of 25 mm; the tensile measurements of single ultrafine

fibers reported in a previous study were used as a reference14. The fibers were loaded on a specific rectangular frame. The mechanical strength of the MXene fibers was calculated by dividing

the force by the cross-sectional area. The electrical conductivity of the MXene fibers was measured using a multimeter (DMM 7510 1/2, Keithley Instruments, USA) via the four-point probe

method. Four electrodes were separated by a distance of 0.4 mm. Since the conductivity of MXene fibers is highly affected by the atmospheric humidity, the measurement was made in a dry

chamber. The conductivity (_ρ_) of a single fiber was calculated according to Eq. (1) as follows46: $$\rho = \frac{{\pi d^2R}}{{4L}}$$ (1) where _d_ is the diameter, _R_ is the electrical

resistance, and _L_ is the length of the fiber. The diameter of the fiber was calculated based on the cross-sectional area measured in the scanning electron microscope (Supplementary Fig.

7). PREDICTION OF PHASE CHANGE USING THE ONSAGER MODEL To predict the critical value of the anisotropic phase, we measured the distribution of the MXene monolayer lateral sizes

(Supplementary Fig. S1c) and found a reasonable agreement with the Onsager model for lyotropic liquid crystals in a disk formulation. The concentration (mass fraction) at the

isotropic–nematic phase transition (_C_, the critical value) was calculated according to Eq. (2) as follows33: $$\frac{d}{I} \approx 5\frac{{\rho _{\mathrm{{{MXene}}}}}}{{\rho

_{\mathrm{{{suspension}}}}}}C^{ - 1}$$ (2) where _d_ and _l_ are the lateral size and thickness of the MXene nanosheets, respectively; _ρ_MXene is the true material density (5.2 g cm3)47;

and _C_ is the concentration (mass fraction) at the isotropic–nematic phase transition. DATA AVAILABILITY The datasets generated during and/or analyzed during the current study are available

from the corresponding author on reasonable request. Source data are provided with this paper. REFERENCES * Compton, O. C. & Nguyen, S. T. Graphene oxide, highly reduced graphene oxide,

and graphene: versatile building blocks for carbon-based materials. _Small_ 6, 711–723 (2010). Article CAS PubMed Google Scholar * Mas-Balleste, R., Gomez-Navarro, C., Gomez-Herrero, J.

& Zamora, F. 2D materials: to graphene and beyond. _Nanoscale_ 3, 20–30 (2011). Article ADS CAS PubMed Google Scholar * Liu, J. et al. Hydrophobic, flexible, and lightweight MXene

foams for high-performance electromagnetic-interference shielding. _Adv. Mater._ 29, 1702364 (2017). Google Scholar * Kurra, N., Ahmed, B., Gogotsi, Y. & Alshareef, H. N. MXene-on-paper

coplanar microsupercapacitors. _Adv. Energy Mater._ 6, 1601372 (2016). Article CAS Google Scholar * Dong, Z. et al. Facile fabrication of light, flexible and multifunctional graphene

fibers. _Adv. Mater._ 24, 1856–1861 (2012). Article CAS PubMed Google Scholar * Chen, C. et al. Functionalized boron nitride membranes with ultrafast solvent transport performance for

molecular separation. _Nat. Commun._ 9, 1902 (2018). Article ADS PubMed PubMed Central CAS Google Scholar * Xia, P., Zhu, B., Yu, J., Cao, S. & Jaroniec, M. Ultra-thin nanosheet

assemblies of graphitic carbon nitride for enhanced photocatalytic CO2 reduction. _J. Mater. Chem. A_ 5, 3230–3238 (2017). Article CAS Google Scholar * Wang, H., Feng, H. & Li, J.

Graphene and graphene-like layered transition metal dichalcogenides in energy conversion and storage. _Small_ 10, 2165–2181 (2014). Article CAS PubMed Google Scholar * Zhu, W. et al.

Black phosphorus flexible thin film transistors at gigahertz frequencies. _Nano Lett._ 16, 2301–2306 (2016). Article ADS CAS PubMed Google Scholar * Sun, Z. et al. Generalized

self-assembly of scalable two-dimensional transition metal oxide nanosheets. _Nat. Commun._ 5, 3813 (2014). Article ADS CAS PubMed Google Scholar * Park, H. et al. Dynamic assembly of

liquid crystalline graphene oxide gel fibers for ion transport. _Sci. Adv._ 4, eaau2104 (2018). Article ADS CAS PubMed PubMed Central Google Scholar * Aboutalebi, S. H. et al.

High-performance multifunctional graphene yarns: toward wearable all-carbon energy storage textiles. _ACS Nano_ 8, 2456–2466 (2014). Article CAS PubMed Google Scholar * Meng, Y. et al.

All-graphene core-sheath microfibers for all-solid-state, stretchable fibriform supercapacitors and wearable electronic textiles. _Adv. Mater._ 25, 2326–2331 (2013). Article CAS PubMed

Google Scholar * Eom, W. et al. Strengthening and stiffening graphene oxide fiber with trivalent metal ion binders. _Part. Part. Syst. Charact._ 34, 1600401 (2017). Article CAS Google

Scholar * Lukatskaya, M. R. et al. Ultra-high-rate pseudocapacitive energy storage in two-dimensional transition metal carbides. _Nat. Energy_ 2, 17105 (2017). Article ADS CAS Google

Scholar * Naguib, M. et al. Two-dimensional nanocrystals produced by exfoliation of Ti3AlC2. _Adv. Mater._ 23, 4248–4253 (2011). Article CAS PubMed Google Scholar * Hantanasirisakul, K.

et al. Fabrication of Ti3C2Tx MXene transparent thin films with tunable optoelectronic properties. _Adv. Electron. Mater._ 2, 1600050 (2016). Article CAS Google Scholar * Peng, Y.-Y. et

al. All-MXene (2D titanium carbide) solid-state Microsupercapacitors for on-chip energy storage. _Energy Environ. Sci._ 9, 2847–2854 (2016). Article CAS Google Scholar * Yang, W. et al.

3D Printing of freestanding MXene architectures for current-collector-free supercapacitors. _Adv. Mater._ 31, 1902725 (2019). Article CAS Google Scholar * Jiang, C. et al. All-electrospun

flexible triboelectric nanogenerator based on metallic MXene nanosheets. _Nano Energy_ 59, 268–276 (2019). Article CAS Google Scholar * Seyedin, S., Yanza, E. R. S. & Razal, J. M.

Knittable energy storing fiber with high volumetric performance made from predominantly MXene nanosheets. _J. Mater. Chem. A_ 5, 24076–24082 (2017). Article CAS Google Scholar * Yang, Q.

et al. MXene/graphene hybrid fibers for high performance flexible supercapacitors. _J. Mater. Chem. A_ 5, 22113–22119 (2017). Article CAS Google Scholar * Wang, Z. et al. High-performance

biscrolled MXene/carbon nanotube yarn supercapacitors. _Small_ 14, 1802225 (2018). Article CAS Google Scholar * Zhang, J. et al. Highly conductive Ti3C2Tx MXene hybrid fibers for

flexible and elastic fiber-shaped supercapacitors. _Small_ 15, 1804732 (2019). Article CAS Google Scholar * Alhabeb, M. et al. Guidelines for synthesis and processing of two-dimensional

titanium carbide (Ti3C2Tx MXene). _Chem. Mater._ 29, 7633–7644 (2017). Article CAS Google Scholar * Lipatov, A. et al. Elastic properties of 2D Ti3C2Tx MXene monolayers and bilayers.

_Sci. Adv._ 4, eaat0491 (2018). Article ADS PubMed PubMed Central CAS Google Scholar * Liu, F. et al. Preparation of Ti3C2 and Ti2C MXenes by fluoride salts etching and methane

adsorptive properties. _Appl. Surf. Sci._ 416, 781–789 (2017). Article ADS CAS Google Scholar * Maleski, K., Mochalin, V. N. & Gogotsi, Y. Dispersions of two-dimensional titanium

carbide MXene in organic solvents. _Chem. Mater._ 29, 1632–1640 (2017). Article CAS Google Scholar * Li, Y. et al. Facile preparation of in situ coated Ti3C2Tx/Ni0.5Zn0.5Fe2O4 composites

and their electromagnetic performance. _RSC Adv._ 7, 24698–24708 (2017). Article CAS Google Scholar * Kim, S. J. et al. Interfacial assembly of ultrathin, functional MXene films. _ACS

Appl. Mater. Interfaces_ 11, 32320–32327 (2019). Article CAS PubMed Google Scholar * Choi, H., Seok Woo, J., Tark Han, J. & Park, S.-Y. Fabrication of water-dispersible single-walled

carbon nanotube powder using N-methylmorpholine N-oxide. _Nanotechnology_ 28, 465706 (2017). Article PubMed CAS Google Scholar * Xia, Y. et al. Thickness-independent capacitance of

vertically aligned liquid-crystalline MXenes. _Nature_ 557, 409–412 (2018). Article ADS CAS PubMed Google Scholar * Guo, F. et al. Hydration-responsive folding and unfolding in graphene

oxide liquid crystal phases. _ACS Nano_ 5, 8019–8025 (2011). Article CAS PubMed PubMed Central Google Scholar * Morris, E. R., Cutler, A., Ross-Murphy, S., Rees, D. & Price, J.

Concentration and shear rate dependence of viscosity in random coil polysaccharide solutions. _Carbohydr. Polym._ 1, 5–21 (1981). Article CAS Google Scholar * Akuzum, B. et al.

Rheological characteristics of 2D titanium carbide (MXene) dispersions: a guide for processing MXenes. _ACS Nano_ 12, 2685–2694 (2018). Article CAS PubMed Google Scholar * Jalili, R. et

al. Formation and processability of liquid crystalline dispersions of graphene oxide. _Mater. Horiz._ 1, 87–91 (2014). Article CAS Google Scholar * Naficy, S. et al. Graphene oxide

dispersions: tuning rheology to enable fabrication. _Mater. Horiz._ 1, 326–331 (2014). Article CAS Google Scholar * Jalili, R. et al. Scalable one‐step wet‐spinning of graphene fibers and

yarns from liquid crystalline dispersions of graphene oxide: towards multifunctional textiles. _Adv. Funct. Mater._ 23, 5345–5354 (2013). Article CAS Google Scholar * Cong, H.-P. et al.

Wet-spinning assembly of continuous, neat, and macroscopic graphene fibers. _Sci. Rep._ 2, 613 (2012). Article PubMed PubMed Central CAS Google Scholar * Xu, Z. & Chao, G. Graphene

chiral liquid crystals and macroscopic assembled fibres. _Nat. Commun._ 2, 571 (2011). Article ADS PubMed PubMed Central CAS Google Scholar * Chen, L. et al. Toward high performance

graphene fibers. _Nanoscale_ 5, 5809–5815 (2013). Article ADS CAS PubMed Google Scholar * Xu, Z. et al. Ultrastrong fibers assembled from giant graphene oxide sheets. _Adv. Mater._ 25,

188–193 (2013). Article CAS PubMed Google Scholar * Xiang, C. et al. Large flake graphene oxide fibers with unconventional 100% knot efficiency and highly aligned small flake graphene

oxide fibers. _Adv. Mater._ 25, 4592–4597 (2013). Article CAS PubMed Google Scholar * Ma, T. et al. A bioinspired interface design for improving the strength and electrical conductivity

of graphene‐based fibers. _Adv. Mater._ 30, 1706435 (2018). Article CAS Google Scholar * Ling, Z. et al. Flexible and conductive MXene films and nanocomposites with high capacitance.

_Proc. Natl Acad. Sci. USA_ 111, 16676–16681 (2014). Article ADS CAS PubMed Google Scholar * Rebouillat et al. Measuring the electrical conductivity of single fibres. _Int. J.

Electrochem. Sci._ 6, 5731–5740 (2011). CAS Google Scholar * Naguib et al. Two-dimensional transition metal carbides. _ACS Nano_ 6, 1322–1331 (2012). Article CAS PubMed Google Scholar

Download references ACKNOWLEDGEMENTS The authors thank the Basic Science Research Program (2017R1A2B4010771 and 2016R1A6A1A03013422) of the National Research Foundation of Korea funded by

the Ministry of Science, ICT & Future Planning. The prepared samples were analyzed using TEM, XPS, and XRD instruments installed at the Hanyang LINC Analytical Equipment Center (Seoul).

AUTHOR INFORMATION Author notes * These authors contributed equally: Wonsik Eom, Hwansoo Shin, Rohan B. Ambade. AUTHORS AND AFFILIATIONS * Department of Organic and Nano Engineering, Hanyang

University, Seoul, 04763, Republic of Korea Wonsik Eom, Hwansoo Shin, Rohan B. Ambade, Sang Hoon Lee, Ki Hyun Lee, Dong Jun Kang & Tae Hee Han * Research Institute of Industrial

Science, Hanyang University, Seoul, 04763, Republic of Korea Ki Hyun Lee & Tae Hee Han Authors * Wonsik Eom View author publications You can also search for this author inPubMed Google

Scholar * Hwansoo Shin View author publications You can also search for this author inPubMed Google Scholar * Rohan B. Ambade View author publications You can also search for this author

inPubMed Google Scholar * Sang Hoon Lee View author publications You can also search for this author inPubMed Google Scholar * Ki Hyun Lee View author publications You can also search for

this author inPubMed Google Scholar * Dong Jun Kang View author publications You can also search for this author inPubMed Google Scholar * Tae Hee Han View author publications You can also

search for this author inPubMed Google Scholar CONTRIBUTIONS Conceptualization, T.H.H.; methodology and investigation, W.E., H.S., R.B.A., S.H.L., K.H.L., D.J.K., and T.H.H.; supervision,

T.H.H.; W.E., H.S., R.B.A., S.H.L., K.H.L., D.J.K., and T.H.H. contributed to the writing of, reading of, and commenting on the manuscript. CORRESPONDING AUTHOR Correspondence to Tae Hee

Han. ETHICS DECLARATIONS COMPETING INTERESTS The authors declare no competing interests. ADDITIONAL INFORMATION PEER REVIEW INFORMATION _Nature Communications_ thanks Zong-Huai Liu and

other, anonymous, reviewers for their contributions to the peer review of this work. Peer review reports are available. PUBLISHER’S NOTE Springer Nature remains neutral with regard to

jurisdictional claims in published maps and institutional affiliations. SUPPLEMENTARY INFORMATION SUPPLEMENTARY INFORMATION PEER REVIEW FILE SUPPLEMENTARY AUDIO SUPPLEMENTARY MOVIE SOURCE

DATA SOURCE DATA RIGHTS AND PERMISSIONS OPEN ACCESS This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation,

distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons license, and

indicate if changes were made. The images or other third party material in this article are included in the article’s Creative Commons license, unless indicated otherwise in a credit line to

the material. If material is not included in the article’s Creative Commons license and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will

need to obtain permission directly from the copyright holder. To view a copy of this license, visit http://creativecommons.org/licenses/by/4.0/. Reprints and permissions ABOUT THIS ARTICLE

CITE THIS ARTICLE Eom, W., Shin, H., Ambade, R.B. _et al._ Large-scale wet-spinning of highly electroconductive MXene fibers. _Nat Commun_ 11, 2825 (2020).

https://doi.org/10.1038/s41467-020-16671-1 Download citation * Received: 14 November 2019 * Accepted: 11 May 2020 * Published: 04 June 2020 * DOI: https://doi.org/10.1038/s41467-020-16671-1

SHARE THIS ARTICLE Anyone you share the following link with will be able to read this content: Get shareable link Sorry, a shareable link is not currently available for this article. Copy to

clipboard Provided by the Springer Nature SharedIt content-sharing initiative