- Select a language for the TTS:

- UK English Female

- UK English Male

- US English Female

- US English Male

- Australian Female

- Australian Male

- Language selected: (auto detect) - EN

Play all audios:

ABSTRACT Superplasticity describes a material’s ability to sustain large plastic deformation in the form of a tensile elongation to over 400% of its original length, but is generally

observed only at a low strain rate (~10−4 s−1), which results in long processing times that are economically undesirable for mass production. Superplasticity at high strain rates in excess

of 10−2 s−1, required for viable industry-scale application, has usually only been achieved in low-strength aluminium and magnesium alloys. Here, we present a superplastic elongation to

2000% of the original length at a high strain rate of 5 × 10−2 s−1 in an Al9(CoCrFeMnNi)91 (at%) high-entropy alloy nanostructured using high-pressure torsion. The high-pressure torsion

induced grain refinement in the multi-phase alloy combined with limited grain growth during hot plastic deformation enables high strain rate superplasticity through grain boundary sliding

accommodated by dislocation activity. SIMILAR CONTENT BEING VIEWED BY OTHERS A HIGH-ENTROPY ALLOY SHOWING GIGAPASCAL SUPERELASTIC STRESS AND NEARLY TEMPERATURE-INDEPENDENT MODULUS Article

Open access 31 January 2025 HIERARCHICAL MICROSTRUCTURE STRENGTHENING IN A SINGLE CRYSTAL HIGH ENTROPY SUPERALLOY Article Open access 22 July 2020 EVADING DYNAMIC STRENGTH AND DUCTILITY

TRADE-OFF IN A HIGH-ENTROPY ALLOY VIA LOCAL CHEMICAL ORDERING Article Open access 15 April 2023 INTRODUCTION Superplasticity is generally observed in fine-grained materials at low strain

rates (10−4–10−3 s−1) and high homologous temperatures (>0.5 Tm), where Tm is the melting temperature1,2,3. Over the past few decades, achieving superplasticity at high-strain rates

(>10−2 s−1) has garnered wide attention from researchers as it possesses great advantage of reducing the forming time, making it economically viable for industries4,5. However, High

Strain-Rate Superplasticity (HSRS) is extremely rare in high-strength materials, and in particular, the lack of superplastic forming capability in a recently emerged class of high-strength

materials, the so-called High-Entropy Alloys (HEAs), is a serious obstacle for its potential use in engineering complex structures. HEAs have a unique alloy design concept based on

multi-principle elements, and they exhibit remarkable properties such as high strength combined with high ductility as well as high fracture toughness when compared to conventional

alloys6,7,8. Thus, achieving HSRS in HEAs would signify a huge breakthrough in advanced material science. According to the constitutive equation for superplasticity, a decrease in grain size

is essential to achieve superplasticity at a high-strain rate4,5,9,10. Besides, Grain Boundary Sliding (GBS), the predominant deformation mechanism found in superplastic behavior, is

predominantly observed in materials with small grains and high-angle grain boundaries11,12. More importantly, retention of Ultra-Fine Grains (UFGs) or nanoscale grains without significant

grain growth at elevated temperatures is essential to accommodate GBS and GBS-induced cavitation through diffusion or dislocation motion11,13,14. The representative CoCrFeMnNi HEA with a

single Face-Centered Cubic (FCC) structure exhibited a reasonable superplastic elongation of 570% at elevated temperature15. There is a consensus that a multi-phase structure potentially

shows higher elongation as compared with a single-phase structure due to grain growth suppression during the superplasticity test1,10. In most of the HEAs, the addition of Al has been

demonstrated to form an ordered Body-Centered Cubic (B2) phase and it is shown to enhance the room temperature mechanical properties16,17,18. It has been reported that the B2 phase in

Alx(CoCrFeMnNi)100-x forms when the Al content is above 8 at%, and a drastic decrease in ductility is observed when the Al content is more than 11 at%19. Consequently, in the present study,

we chose Al9(CoCrFeMnNi)91 HEA based on the abovementioned logical reasoning and engineered a unique nanostructured dual-phase microstructure. Here, we fabricate an Al9(CoCrFeMnNi)91 HEA

with nano-sized FCC grains and B2 phase in the range of a few hundred nanometers to micrometers through thermo-mechanical treatment followed by high-pressure torsion (HPT) processing. Among

several processing routes, the HPT is the most effective route to produce bulk materials with very fine grain size20,21,22. The presence of B2 phase and the newly formed sigma phase during

superplastic testing assist in preventing significant grain growth, favoring GBS with high-strain-rate sensitivity value. The GBS is observed to be accommodated by interlinkage of cavities,

and dislocation activities in FCC and B2 phases. The fine grain size accompanied by high-strain-rate sensitivity and GBS accommodation by plastic deformation lead to an ultra-high

superplasticity of 2000% at a high-strain rate of 5 × 10−2 s−1 in the present alloy. Considering the unique properties reported in HEAs and the HSRS achieved in the present work, HEAs show

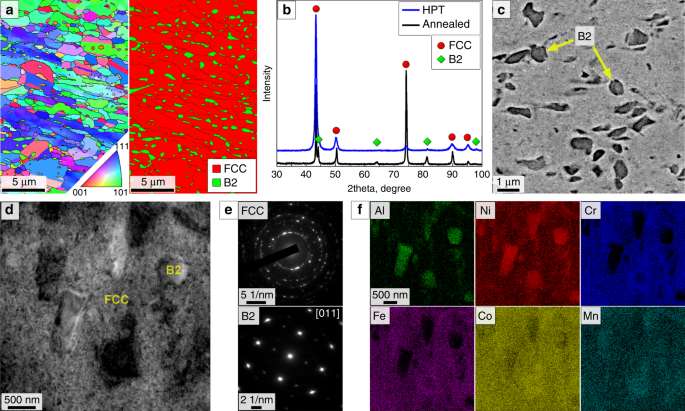

the potential to be an emerging advanced materials for future structural applications with complex shapes. RESULTS AND DISCUSSION INITIAL MICROSTRUCTURE The initial microstructure shows FCC

and Al–Ni-rich B2 phases before superplastic tensile tests (Fig. 1). The as-annealed specimen displays (Fig. 1a) fine FCC grains (average size of ~2 μm) with relatively large B2 precipitates

(800 nm–1 µm) at the boundaries of FCC grains, and small B2 precipitates inside the FCC grains (200–400 nm)17,23,24. The X-Ray Diffraction (XRD) patterns of the as-annealed and as-HPT

specimens show the peaks of FCC and B2 phases (Fig. 1b), we can see peak broadening occurs after HPT due to grain refinement and lattice distortion. The Backscattered Electron (BSE) image

(Fig. 1c) displays how the B2 phase endured severe strain without a significant reduction in size after HPT23. Transmission Electron Microscopy (TEM) investigation with a corresponding

Selected Area Electron Diffraction (SAED) pattern of the as-HPT specimen demonstrates the presence of a nanostructured FCC phase (Fig. 1d and Supplementary Fig. 1) as well as relatively fine

B2 phase. Energy-Dispersive Spectroscopy (EDS) analysis reveals that the B2 phase is rich in Al and Ni. During the HPT process, the soft FCC grains undergo severe strain, which leads to

significant grain refinement, and at the same time, the hard B2 phase flows alongside the soft FCC phase and retains its size23. This leads to a unique dual microstructure of nano-sized FCC

matrix with a B2 phase in the range of a few hundred nanometers to micrometers. SUPERPLASTIC BEHAVIOR Figure 2a displays the representative engineering stress-strain curves under different

testing conditions. The specimens fractured during tensile tests are shown in Fig. 2b and Supplementary Fig. 2. Initially, elongation to failure lengths enhanced proportionally with

increasing temperature with the elongation at 873 K being just 430%. Then, superplastic elongation suddenly soared up to 1260% at 973 K. The maximum elongation reached during our tests was

2000% at a temperature of 1073 K under a strain rate of 5 × 10−2 s−1. Tensile deformed specimens at temperatures of 973 and 1073 K proceeded uniformly without any necking seen at any of the

tested strain rates (Fig. 2b and Supplementary Fig. 2). The strain-rate sensitivity (_m)_ is a critical parameter used to characterize the ability of metals to resist necking during the

deformation. The strain-rate sensitivity can be defined by \(m = \partial \ln \sigma /\partial \ln \dot \varepsilon\), where _σ_ and \(\dot \varepsilon\) denote the flow stress and plastic

strain-rate, respectively. This is shown in Fig. 2c, where the squared R indicates the coefficient of determination. The estimated _m_ value increases with increasing temperature and is very

close to the ideal value of 0.5 required for superplasticity at 1073 K1. Higher elongations at 973 K and 1073 K, and relative lower elongation at 673 K could be attributed to the estimated

_m_ values at these temperatures because high _m_ can decelerate the necking and assist homogeneous deformation25,26,27. The high value of _m_ also implies that the dominant mechanism of

superplastic deformation is associated with GBS1,28,29. Besides, HPT processing can produce nanoscale grains with a high fraction of high-angle boundaries, thus enabling GBS to occur

easily30,31,32. The presence of quasi-stable flow is numerically verified by this _m_ value above and beyond the visual proof of the homogenous elongated specimen’s gauge length. To the best

of our knowledge, the elongation to failure result of 2000% achieved in this work is the largest elongation ever reported for HEA and also represents a new record for elongation among the

numerous HSRS investigations on conventional alloys10,33. Strikingly, the elongation to failure results achieved in this study using a high-strength material is even considered large when

compared to conventional superplastic alloys that have low strength at room temperature24,34,35,36. The 2000% elongation in this study far exceeds the 1240% figure reported for wrought

AlCoCrCuMnNi HEA10. Furthermore, the maximum elongation in this study (2000%) was achieved at a lower temperature (1073 K) than for the AlCoCrCuMnNi HEA (1273 K) and with a far faster strain

rate of 5 × 10−2 s−1 compared to 10−2 s−1 for AlCoCrCuMnNi. The liquidus temperature of AlCoCrCuMnNi, calculated from CALPHAD, is 1501 K, and this is very similar to 1567 K of the present

HEA (Supplementary Fig. 3). The difference in superplastic elongations at 1073–1273 K is notable for these HEAs during thermo-plastic processing10,37. From the domain of superplasticity

research that utilizes HPT processing, the present HEA still has the best elongation result compared to the highest previously reported elongation of 1800% for illustrious Zn-22% Al alloy38.

It is worth mentioning that the high superplasticity seen in the present work was recorded for a tensile sample with a small cross-sectional area. It has been established in superplasticity

literature on severely plastic deformed samples that small cross-sectional area lead to relatively low elongation33. For instance, relatively higher elongation has been observed in Zn-22%

Al alloy processed by Equal-Channel Angular Pressing (ECAP) compared to HPT-processed samples, this lower elongation in the HPT-processed sample is attributed to its small cross-sectional

area compared to the ECAP sample38. SUPERPLASTICITY MECHANISM Microstructural investigations of the superplastic tensile sample at 2000% elongation from various positions along the deformed

specimen are shown in Fig. 3. We can see the cavity strings are in alignment with the applied tension direction (Fig. 3b). Strikingly, the Scanning Transmission Electron Microscopy (STEM)

images show that there is no considerable grain size difference between the deformed (gauge) and nondeformed (grip) parts (Fig. 3c–e), this indicates an almost total absence of dynamic grain

growth in the deformed region39. The TEM-EDS analysis of the specimens tested at 1073 K shows the formation of sigma phase (rich in Cr) during the superplasticity tests in addition to the

presence of FCC and B2 phases (Supplementary Fig. 4). The high-strain-rate and presence of B2 and sigma phases limit grain growth during superplastic deformation, leading to a

quasi-theoretical _m_ value. Also, the grain morphology changes from an equiaxed shape at the grip to semi-equiaxed morphology at the tip. High Resolution (HR)- TEM images from the interface

of FCC and B2 phases at the grip are shown by Fig. 3f and at the tip are shown by Fig. 3g. Corresponding Fast Fourier Transform (FFT)- generated SAED patterns expose the presence of a

Kurdjumov–Sachs (K–S) Orientation Relationship (OR; depicted by the blue circle) at the grip. However, there is no specific OR between FCC and B2 phases at the tip. Maintaining UFG and

near-equiaxed morphology during the superplasticity test confirms the occurrence of GBS1. Elimination of OR between FCC and B2 points toward the occurrence of GBS that accommodates grain

rotation during the superplasticity test40. In addition, the generation of the high dislocation density seen mainly in FCC and B2 grains (Supplementary Fig. 5) along with the evolution of

the semi-equiaxed morphology at the tip suggests the role of intragranular dislocations for the accommodation of plastic deformation during the superplasticity test9,41. However, the

formation of intragranular dislocation in the sigma phase was not observed. The HR-TEM images taken from the interface show a high dislocation density around the interphase boundaries in the

tip (Supplementary Figs. 6–8). Looking at the above evidence, we can say the different phases in the present multi-phase HEA demonstrate quite a heterogeneous mechanical response at the

scale of individual grains during the superplasticity test. It can be concluded that the sigma phase may play the role of a hard domain in the present HEA and Geometrically Necessary

Dislocations (GNDs) can be generated in the softer domains to maintain interphase boundary compatibility42. Accordingly, the concurrent process of GBS and GBS being accommodated by

intragranular dislocation and the generation of GNDs come together to contribute to the record elongation by postponing the initiation of cracks at interphase boundaries. A detailed survey

on the superplasticity of HEAs shows that the accommodation of GBS by dislocation activity is rather limited43. CAVITY INTERLINKAGE Cavity damage due to GBS can be restricted by the rare

interlinkage of cavity strings under plasticity-controlled cavity growth21,44. The width of cavity strings is on the order of grain size and originates at the interphase of FCC and B2

phases9 (Supplementary Fig. 9). Cavities tend to grow along FCC grains parallel to the tensile direction and get blocked by B2 and sigma grains4,45. The ease of cavity interlinkage is

manipulated by the interleaved microstructure of the present HEA, and this has the crucial impact of making it easy to retain quasi-stable plastic flow46. In HSRS, partial melting is

suggested as one of the accommodation mechanisms to assist GBS due to the formation of a liquid-phase film at the boundaries47,48. However, TEM-EDS line-scanning at different interphase

boundaries at the tip revealed a sharp change in the chemical compositions without any evidence of partial melting (i.e., segregation of an element or formation of an intermediate phase) at

the boundaries in the present HEA (Supplementary Fig. 10). In summary, this work shows that it is possible to achieve ultra-high HSRS in HEA through microstructural engineering. The

formation of dual-phase microstructure during HPT and the subsequent formation of a sigma phase led to a multi-phase UFG microstructure during deformation. This UFG microstructure improves

GBS efficiency leading to steady-state plastic flow and an estimated _m_ value close to the ideal value. In addition, the interlinkage of cavities and the dislocation motion in FCC and B2

phases reduce stress concentrations and play a vital role in accommodating GBS. Consequently, the present multi-phase microstructure is able to achieve an ultra-high HSRS with a the record

of 2000% elongation that is significantly greater than anything seen in previous investigations from the severe plastic deformation society and HEA community. In addition, the unique

properties of HEAs together with this ultra-high HSRS make HEAs even more attractive for aerospace and automobile industries. We propose that the practical improvement of superplasticity in

HEA materials can be obtained by taking advantage of a multi-phase UFG structure. METHODS SAMPLE PREPARATION AND SUPERPLASTICITY TENSILE TESTS The Al9(CoCrFeMnNi)91 (at%) HEA was produced

from elements with a purity of 99.99% by vacuum induction melting. The as-cast ingot was homogenized at 1473 K for 12 h, followed by water quenching. The ingot was subjected to cold-rolling

to reduce its thickness from 7 to 1.5 mm, and this corresponds to a 78.6% reduction. The cold-rolled ingot was annealed at 1273 K for 15 min in argon gas, followed by water quenching. Discs

with a diameter of 10 mm were machined from the annealed plate through electric discharge machining. The 10 mm discs were processed by five revolutions of HPT at room temperature under an

applied pressure of 6 GPa with an anvil rotation rate of 1 revolution per minute. Differential Scanning Calorimetry (DSC) measurements, using the SETARAM LABSYS evo DTA/DSC instrument, were

conducted on a piece of the HPT-processed sample (~100 mg). The HPT sample was loaded into a ceramic pan and then heated from room temperature to melting temperature with a heating rate of

10 K/min in a nitrogen gas atmosphere. The flow rate of the N2 gas was controlled to remain at 50 mL/min. The absolute melting temperature from DSC was employed to determine the testing

temperatures used in the superplasticity experiments. Flat dog-bone-shaped specimens were machined symmetrically from the as-HPT disks with the gauge’s position set at 2.5 mm away from the

center. The gauge dimensions are 1.5 mm in length, 1.0 mm in width, and 0.7 mm in thickness. The specimens were firmly assembled to a pair of nonslippery clamps at the grip parts by nuts,

then subjected to tension tests using an Instron 8862 instrument. The specimens were well aligned to be parallel with the pulling shaft. The specimens were heated from room temperature to

the target superplastic testing temperatures of 873, 973, and 1073 K by halogen furnace (DF-60HG, DaeHeung Co., Korea) in the air atmosphere. After the stabilization of temperature with a

dwell time of 7 min, the specimens were preloaded until 5 N to remove the thermal expansion effect of the system. Then, a traction load was applied until the fracture. The failure specimens

were promptly immersed in water to preserve their microstructure. Three tests were carried out in each condition to ensure the reproducibility of results. The elongation was measured using

the recorded displacement from the Instron data with a step size of 1 s on each different strain rate. In addition, the obtained elongation values were confirmed by evaluating the

superplastic fractured samples using an optical microscope. MICROSTRUCTURAL CHARACTERIZATION The Transmission Electron Microscope (TEM) specimens of the as-HPT and grip of the superplastic

specimens were prepared by mechanical grinding to a thickness of ~60 μm, and they were then thinned using electro-polishing with a solution of 10% HClO4 and 90% CH3COOH at an applied voltage

of 25 V at room temperature. The TEM foils from the middle and tip of superplastic specimens were carried out using the Focused Ion Beam (FIB) lift-out procedure. The TEM analysis was

undertaken by the JEM-2100F (JEOL, Japan) instrument. The surface of specimens was polished to a mirror-like finish using diamond paste and colloidal silica suspension for the following

analysis. Phase identification was determined by X-Ray Diffraction (XRD) using the Rigaku D/MAX-2500 XRD instrument employing Cu Kα radiation with a wavelength of 0.154 nm. The XRD pattern

was acquired in a 2θ range of 30–100° at a scan rate of 1° per min and a scan-interval of 0.02°. The microstructure of the annealed specimen was observed using Electron Backscatter

Diffraction (EBSD), performed by a Field Emission-Scanning Electron Microscope (FE-SEM; Quanta 3D, FEI Company, USA). The obtained data were analyzed using Orientation Imaging Microscopy

(OIM) analysis software (TSL OIM analysis 7). DATA AVAILABILITY The data that support the findings of this study are available from the corresponding author upon reasonable request. CHANGE

HISTORY * _ 02 FEBRUARY 2022 A Correction to this paper has been published: https://doi.org/10.1038/s41467-022-28422-5 _ REFERENCES * Langdon, T. G. Seventy-five years of superplasticity:

historic developments and new opportunities. _J. Mater. Sci._ 44, 5998–6010 (2009). Article ADS CAS Google Scholar * McFadden, S. X., Mishra, R. S., Valiev, R. Z., Zhilyaev, A. P. &

Mukherjee, A. K. Low-temperature superplasticity in nanostructured nickel and metal alloys. _Nature_ 398, 684–686 (1999). Article ADS CAS Google Scholar * Berdichevskij, E. G. Use of the

superplasticity effect of materials in engineering technology. _IOP Conf. Ser. Mater. Sci. Eng._ 441, 012009 (2018). Article Google Scholar * Park, K. T., Hwang, D. Y., Lee, Y. K., Kim,

Y. D. & Shin, D. H. High strain rate superplasticity of submicrometer grained 5083 Al alloy containing scandium fabricated by severe plastic deformation. _Mater. Sci. Eng. A_ 341,

273–281 (2003). Article Google Scholar * Musin, F., Kaibyshev, R., Motohashi, Y. & Itoh, G. High strain rate superplasticity in a commercial Al–Mg–Sc alloy. _Scr. Mater._ 50, 511–516

(2004). Article CAS Google Scholar * Ye, Y. Z., Wang, Q., Lu, J., Liu, C. T. & Yang, Y. High-entropy alloy: challenges and prospects. _Mater. Today_ 19, 349–362 (2016). Article CAS

Google Scholar * Zhang, Y. et al. Microstructures and properties of high-entropy alloys. _Prog. Mater. Sci._ 61, 1–93 (2014). Article CAS Google Scholar * Praveen, S. & Kim, H. S.

High-entropy alloys: potential candidates for high-temperature applications–an overview. _Adv. Eng. Mater._ 20, 1700645 (2018). Article CAS Google Scholar * Kim, B. N., Hiraga, K.,

Morita, K. & Sakka, Y. A high-strain-rate superplastic ceramic. _Nature_ 413, 288–291 (2001). Article ADS CAS PubMed Google Scholar * Shaysultanov, D. G., Stepanov, N. D.,

Kuznetsov, A. V., Salishchev, G. A. & Senkov, O. N. Phase composition and superplastic behavior of a wrought AlCoCrCuFeNi high-entropy alloy. _JOM_ 65, 1815–1828 (2013). Article ADS

CAS Google Scholar * Mohamed, F. A. Creep and superplasticity: evolution and rationalization. _Adv. Eng. Mater._ 22, 1900532 (2020). Article CAS Google Scholar * Watanabe, T.,

Tsurekawa, S., Kobayashi, S. & Yamaura, S. Structure-dependent grain boundary deformation and fracture at high temperatures. _Mater. Sci. Eng. A_ 410, 140–147 (2005). Article CAS

Google Scholar * Chokshi, A. H. & Langdon, T. G. A model for diffusional cavity growth in superplasticity. _Acta Metall._ 35, 1089–1101 (1987). Article CAS Google Scholar * Wei, Y.,

Bower, A. F. & Gao, H. Recoverable creep deformation due to heterogeneous grain-boundary diffusion and sliding. _Scr. Mater._ 57, 933–936 (2007). Article CAS Google Scholar * Shahmir,

H., He, J., Lu, Z., Kawasaki, M. & Langdon, T. G. Evidence for superplasticity in a CoCrFeNiMn high-entropy alloy processed by high-pressure torsion. _Mater. Sci. Eng. A_ 685, 342–348

(2017). Article CAS Google Scholar * Choudhuri, D. et al. Enhancing strength and strain hardenability via deformation twinning in fcc-based high entropy alloys reinforced with

intermetallic compounds. _Acta Mater._ 165, 420–430 (2019). Article ADS CAS Google Scholar * Chen, S. et al. Temperature effects on the serrated behavior of an Al0.5CoCrCuFeNi

high-entropy alloy. _Mater. Chem. Phys._ 210, 20–28 (2018). Article CAS Google Scholar * Sathiyamoorthi, P. et al. Achieving high strength and high ductility in Al0.3CoCrNi medium-entropy

alloy through multi-phase hierarchical microstructure. _Materialia_ 8, 100442 (2019). Article CAS Google Scholar * He, J. H. et al. Effects of Al addition on structural evolution and

tensile properties of the FeCoNiCrMn high-entropy alloy system. _Acta Mater._ 62, 105–113 (2014). Article ADS CAS Google Scholar * Asghari-Rad, P. et al. Effect of initial grain size on

deformation mechanism during high-pressure torsion in V10Cr15Mn5Fe35Co10Ni25 high-entropy alloy. _Adv. Eng. Mater._ 22, 1900587 (2020). Article CAS Google Scholar * Nguyen, N. T.-C. et

al. Superplasticity of V10Cr15Mn5Fe35Co10Ni25 high-entropy alloy processed using high-pressure torsion. _Mater. Sci. Eng. A_ 764, 138198 (2019). Article CAS Google Scholar * Asghari-Rad,

P. et al. Fine-tuning of mechanical properties in V10Cr15Mn5Fe35Co10Ni25 high-entropy alloy through high-pressure torsion and annealing. _Mater. Sci. Eng. A_ 771, 138604 (2020). Article CAS

Google Scholar * Reddy, T. S. et al. Severe plastic deformation driven nanostructure and phase evolution in a Al0.5CoCrFeMnNi dual phase high entropy alloy. _Intermetallics_ 91, 150–157

(2017). Article CAS Google Scholar * Park, J. M. et al. Effect of annealing heat treatment on microstructural evolution and tensile behavior of Al0.5CoCrFeMnNi high-entropy alloy. _Mater.

Sci. Eng. A_ 728, 251–258 (2018). Article CAS Google Scholar * Hart, E. W. Theory of the tensile test. _Acta Metall._ 15, 351–355 (1967). Article CAS Google Scholar * Wei, Y. &

Gao, H. An elastic–viscoplastic model of deformation in nanocrystalline metals based on coupled mechanisms in grain boundaries and grain interiors. _Mater. Sci. Eng. A_ 478, 16–25 (2008).

Article CAS Google Scholar * Takai, R., Kimura, S., Kashichi, R., Kotaki, H. & Yoshida, M. Grain refinement effects on the strain rate sensitivity and grain boundary sliding in

partially solidified Al–5 wt% Mg alloy. _Mater. Sci. Eng. A_ 667, 417–425 (2016). Article CAS Google Scholar * Nieh, T. G., Kaibyshev, R., Hsiung, L. M., Nguyen, N. & Wadworth, J.

Subgrain formation and evolution during the deformation of an Al-Mg-Sc alloy at elevated temperatures. _Scr. Mater._ 36, 1011–1016 (1997). Article CAS Google Scholar * Pu, H. P., Liu, F.

C. & Huang, J. C. Characterization and analysis of low-temperature superplasticity in 8090 Al-Li alloys. _Metall. Mater. Trans. A_ 26, 1153–1166 (1995). Article Google Scholar * Park,

K. T., Hwang, D. Y., Chang, S. Y. & Shin, D. H. Low-temperature superplastic behavior of a submicrometer-grained 5083 Al alloy fabricated by severe plastic deformation. _Metall. Mater.

Trans. A_ 33, 2859–2867 (2002). Article Google Scholar * Kawasaki, M. & Langdon, T. G. Review: achieving superplasticity in metals processed by high-pressure torsion. _J. Mater. Sci._

49, 6487–6496 (2014). Article ADS CAS Google Scholar * Fukutomi, H., Yamamoto, T., Nonomura, K. & Takada, K. Examination of dislocation mechanism on grain boundary sliding in high

angle grain boundaries by stress change test. _Interface Sci._ 7, 141–146 (1999). Article CAS Google Scholar * Kawasaki, M. & Langdon, T. G. The contribution of severe plastic

deformation to research on superplasticity. _Mater. Trans._ 60, 1123–1130 (2019). Article CAS Google Scholar * Nieh, T. G., Wadsworth, J. & Sherby, O. D. _Superplasticity in Metals

and Ceramics_. (Cambridge Univ. Press, Cambridge, 1997). * Kawasaki, M., Figueiredo, R. B. & Langdon, T. G. The requirements for superplasticity with an emphasis on magnesium alloys.

_Adv. Eng. Mater._ 18, 127–131 (2016). Article CAS Google Scholar * Bhatta, L. et al. Recent development of superplasticity in aluminum alloys: a review. _Metals_ 10, 77 (2020). Article

CAS Google Scholar * Yue, T. M., Xie, H., Lin, X., Yang, H. O. & Meng, G. H. Solidification behaviour in laser cladding of AlCoCrCuFeNi high-entropy alloy on magnesium substrates. _J.

Alloy. Compd._ 587, 588–593 (2014). Article CAS Google Scholar * Kawasaki, M. & Langdon, T. G. Developing superplasticity and a deformation mechanism map for the Zn–Al eutectoid alloy

processed by high-pressure torsion. _Mater. Sci. Eng. A_ 528, 6140–6145 (2011). Article CAS Google Scholar * Kim, B. N., Hiraga, K., Sakka, Y. & Ahn, B. W. A grain-boundary diffusion

model of dynamic grain growth during superplastic deformation. _Acta Mater._ 47, 3433–3439 (1999). Article ADS CAS Google Scholar * Clark, M. A. & Alden, T. H. Deformation enhanced

grain growth in a superplastic Sn-1% Bi alloy. _Acta Met._ 21, 1195–1206 (1973). Article CAS Google Scholar * Ball, A. & Hutchison, M. M. Superplasticity in the Aluminum–Zinc

eutectoid. _Met. Sci. J._ 3, 1–7 (1969). Article Google Scholar * Wu, X. & Zhu, Y. Heterogeneous materials: a new class of materials with unprecedented mechanical properties. _Mater.

Res. Lett._ 5, 527–532 (2017). Article CAS Google Scholar * Chokshi, A. H. Grain boundary processes in strengthening, weakening, and superplasticity. _Adv. Eng. Mater._ 22, 1900748

(2020). Article CAS Google Scholar * Nieh, T. G., Hsiung, L. M., Wadsworth, J. & Kaibyshev, R. High strain rate superplasticity in a continuously recrystallized Al–6%Mg–0.3%Sc alloy.

_Acta Mater._ 46, 2789–2800 (1998). Article ADS CAS Google Scholar * Leng, Z. et al. Superplastic behavior of extruded Mg–9RY–4Zn alloy containing long period stacking ordered phase.

_Mater. Sci. Eng. A_ 576, 202–206 (2013). Article CAS Google Scholar * Langdon, T. G. Fracture processes in superplastic flow. _Met. Sci._ 16, 175–183 (1982). Article Google Scholar *

Mabuchi, M. & Higashi, K. On accommodation helper mechanism for superplasticity in metal matrix composites. _Acta Mater._ 47, 1915–1922 (1999). Article ADS CAS Google Scholar *

Wakai, F. et al. A superplastic covalent crystal composite. _Nature_ 344, 421–423 (1990). Article ADS CAS Google Scholar Download references ACKNOWLEDGEMENTS This investigation was

supported by the Creative Materials Discovery Program through the National Research Foundation of Korea (NRF) granted by the Ministry of Science and ICT (2016M3D1A1023384). P.S. was funded

by the Korea Research Fellowship program through the National Research Foundation of Korea (NRF) sponsored by the Ministry of Science and ICT (2017H1D3A1A01013666). We have gratefully

received the advisory from Dr. Jongun Moon from POSTECH and Dr. Hamed Shahmir from the University of Sheffield, England. AUTHOR INFORMATION Author notes * These authors contributed equally:

Nhung Thi-Cam Nguyen, Peyman Asghari-Rad. AUTHORS AND AFFILIATIONS * Department of Materials Science and Engineering, Pohang University of Science and Technology (POSTECH), Pohang, 37673,

South Korea Nhung Thi-Cam Nguyen, Peyman Asghari-Rad, Praveen Sathiyamoorthi & Hyoung Seop Kim * Center for High Entropy Alloys, Pohang University of Science and Technology (POSTECH),

Pohang, 37673, South Korea Nhung Thi-Cam Nguyen, Peyman Asghari-Rad, Praveen Sathiyamoorthi & Hyoung Seop Kim * Graduate Institute of Ferrous Technology, Pohang University of Science and

Technology (POSTECH), Pohang, 37673, South Korea Alireza Zargaran, Chong Soo Lee & Hyoung Seop Kim Authors * Nhung Thi-Cam Nguyen View author publications You can also search for this

author inPubMed Google Scholar * Peyman Asghari-Rad View author publications You can also search for this author inPubMed Google Scholar * Praveen Sathiyamoorthi View author publications You

can also search for this author inPubMed Google Scholar * Alireza Zargaran View author publications You can also search for this author inPubMed Google Scholar * Chong Soo Lee View author

publications You can also search for this author inPubMed Google Scholar * Hyoung Seop Kim View author publications You can also search for this author inPubMed Google Scholar CONTRIBUTIONS

N.T-C.N. and P.A-R. contributed equally to this work. N.T-C.N. generated the idea of superplastic alloy component and testing conditions, performed all experiments, processed data, and wrote

the manuscript. P.A-R. conducted the sample preparation for superplastic tests (casting, rolling, HPT), performed the microstructural analysis using TEM and EBSD, and contributed to the

writing and discussion part. S.P. supported the BSE and FIB implementation, revised the text, and contributed to the discussion. A.Z. contributed to the discussion part and accomplished the

TEM works. C.S.L. provided the technical instruction for entire superplastic tensile tests. H.S.K. organized the work, supervised the research progress, and finalized the manuscript.

CORRESPONDING AUTHOR Correspondence to Hyoung Seop Kim. ETHICS DECLARATIONS COMPETING INTERESTS The authors declare no competing interests. ADDITIONAL INFORMATION PEER REVIEW INFORMATION

_Nature Communications_ thanks Peter Liaw and the other, anonymous, reviewer(s) for their contribution to the peer review of this work. Peer reviewer reports are available. PUBLISHER’S NOTE

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations. SUPPLEMENTARY INFORMATION SUPPLEMENTARY INFORMATION PEER REVIEW FILE

RIGHTS AND PERMISSIONS OPEN ACCESS This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and

reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons license, and indicate if changes

were made. The images or other third party material in this article are included in the article’s Creative Commons license, unless indicated otherwise in a credit line to the material. If

material is not included in the article’s Creative Commons license and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain

permission directly from the copyright holder. To view a copy of this license, visit http://creativecommons.org/licenses/by/4.0/. Reprints and permissions ABOUT THIS ARTICLE CITE THIS

ARTICLE Nguyen, N.TC., Asghari-Rad, P., Sathiyamoorthi, P. _et al._ Ultrahigh high-strain-rate superplasticity in a nanostructured high-entropy alloy. _Nat Commun_ 11, 2736 (2020).

https://doi.org/10.1038/s41467-020-16601-1 Download citation * Received: 19 February 2020 * Accepted: 13 May 2020 * Published: 01 June 2020 * DOI: https://doi.org/10.1038/s41467-020-16601-1

SHARE THIS ARTICLE Anyone you share the following link with will be able to read this content: Get shareable link Sorry, a shareable link is not currently available for this article. Copy to

clipboard Provided by the Springer Nature SharedIt content-sharing initiative