- Select a language for the TTS:

- UK English Female

- UK English Male

- US English Female

- US English Male

- Australian Female

- Australian Male

- Language selected: (auto detect) - EN

Play all audios:

ABSTRACT Heterogeneous composite materials with variable local stiffness are widespread in nature, but are far less explored in engineering structural applications. The development of

heterogeneous synthetic composites with locally tuned elastic properties would allow us to extend the lifetime of functional devices with mechanically incompatible interfaces, and to create

new enabling materials for applications ranging from flexible electronics to regenerative medicine. Here we show that heterogeneous composites with local elastic moduli tunable over five

orders of magnitude can be prepared through the site-specific reinforcement of an entangled elastomeric matrix at progressively larger length scales. Using such a hierarchical reinforcement

approach, we designed and produced composites exhibiting regions with extreme soft-to-hard transitions, while still being reversibly stretchable up to 350%. The implementation of the

proposed methodology in a mechanically challenging application is illustrated here with the development of locally stiff and globally stretchable substrates for flexible electronics. You

have full access to this article via your institution. Download PDF SIMILAR CONTENT BEING VIEWED BY OTHERS BIOINSPIRED ELASTOMER COMPOSITES WITH PROGRAMMED MECHANICAL AND ELECTRICAL

ANISOTROPIES Article Open access 26 January 2022 STRAIN-STIFFENING UNIVERSALITY IN COMPOSITE HYDROGELS AND SOFT TISSUES Article 20 May 2025 HIERARCHICALLY STRUCTURED BIOINSPIRED

NANOCOMPOSITES Article 28 November 2022 INTRODUCTION Integration of different synthetic materials, such as polymers, metals and ceramics, into functional devices often results in mismatches

in mechanical and thermal properties that favour premature failure of the solid interfaces due to stress localization. Examples of functional devices whose durability is impaired by

premature interfacial failure are numerous and range from biomedical implants in orthopaedics1 to metal-composite joints in automotive and aerospace applications2,3 to inorganic functional

devices in high-performance flexible electronics4. In some applications, this issue can be circumvented by developing functionally graded heterogeneous materials whose through-thickness

chemical composition is gradually changed to reduce mismatches in the elastic and thermal properties of the homogeneous materials to be integrated. However, this approach has been limited to

purely inorganic systems whose elastic moduli lie within the same order of magnitude, as is the case for example of ceramic thermal barrier coatings deposited on metals5,6. Constructing

heterogeneous composite materials with locally tuned mechanical properties in all three dimensions is a recurring strategy in nature to achieve unusual mechanical properties and to couple

surfaces with very different elastic moduli7,8,9,10,11,12,13,14. For instance, the biological tissue that connects tendons to bone exhibits locally tuned elastic moduli that can vary by as

much as two orders of magnitude to match the stiff surface of bone with the soft tendon15,16,17. This is achieved by changing the local concentration of hydroxyapatite reinforcing particles

embedded within hierarchically structured collagen fibres15. Similarly, the teeth of many vertebrates and invertebrates exhibit a three-dimensional (3D) bilayer structure that combines a

remarkable surface hardness to withstand mastication loads with a high toughness in the inner layer to resist crack propagation. Such properties are achieved by tailoring the concentration

and orientation of reinforcing mineral particles across the material12,18. Although a multitude of other heterogeneous natural composites with locally tuned elastic moduli exist9,18,19,20,

the examples above well illustrate the ability of biological materials to deliberately control its mechanical properties by using an entangled continuous polymer matrix reinforced to

different extents with a limited choice of inorganic reinforcing elements21,22. Such an interpenetrating polymer matrix is believed to be key in ensuring efficient stress transfer and in

avoiding local failure between regions of different elastic moduli. Despite the improved mechanical and thermal interfacial coupling offered by artificial functionally graded heterogeneous

materials, the 3D nature and the unique local control of structure and properties observed in heterogeneous biological composites have not yet been achieved in synthetic systems. Obtaining

such level of 3D control in artificial heterogeneous composites would allow us to not only extend the lifetime of existing functional devices prone to interfacial failure but also to develop

new materials for mechanically challenging demands. These include for example dental restorations for prosthetic dentistry that more closely resemble the mechanical properties of natural

tooth23, elastomeric substrates for flexible electronics that are bendable and stretchable but yet locally stiff24,25,26,27,28,29 and synthetic bio-scaffolds for the replacement of

intervertebral discs30 and for the regeneration of graded tendon/ligament-to-bone insertions31,32,33. In addition to addressing such mechanical challenges, the deliberate local reinforcement

of weak regions achievable with such heterogeneous composites also represents an economical and environmental-friendly approach to attain the required mechanical performance while

minimizing the use of limited and costly resources. Here we show that heterogeneous manufactured composites exhibiting elastic moduli spanning over several orders of magnitude can be

obtained by tuning the local reinforcement of an entangled continuous polymer matrix using reinforcing elements at multiple hierarchical levels. To illustrate the unusual sets of properties

that can be achieved with this approach, we create 3D polymer-based composites whose local elastic modulus on the surface can approach that of the hardest biological materials such as bone

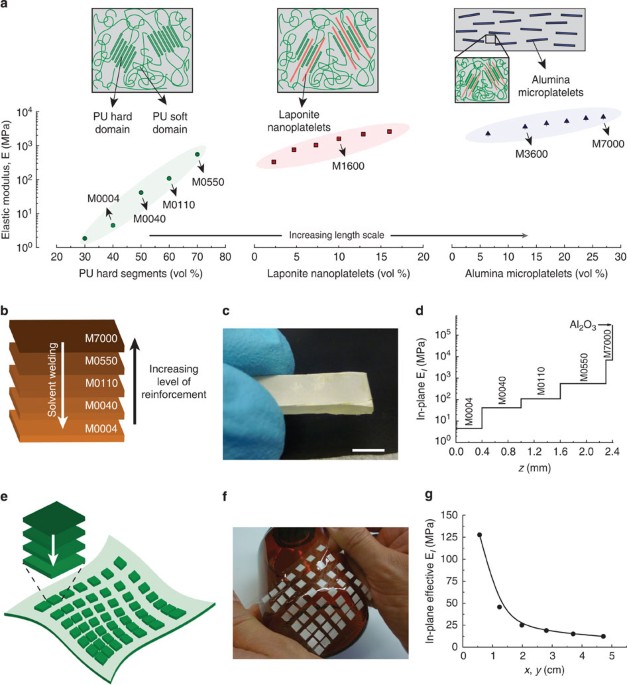

and tooth enamel, whereas still being reversibly stretchable up to 350% strain on a global scale without failure. RESULTS HIERARCHICAL COMPOSITES WITH EXTREME MECHANICAL GRADIENTS Composites

with different elastic moduli were created by hierarchically reinforcing a polyurethane (PU) soft matrix with (1) PU hard segment domains, (2) inorganic nanoplatelets and (3) inorganic

microplatelets at progressively larger length scales (Fig. 1a). Reinforcement of the soft PU matrix with PU hard segments is accomplished by increasing the relative fraction of hard-to-soft

segments (HS:SS) during PU synthesis (Fig. 1a). Further stiffening of PU matrices is achieved through the selective reinforcement of the PU hard domains with laponite nanoplatelets,

following the procedure developed by Liff _et al_.34,35. Alumina microplatelets are finally used to reinforce the laponite-containing PU matrix at the next hierarchical level. Following this

procedure, we produce individual PU films with elastic moduli that can be tuned between 4 MPa and 7 GPa34. In Fig. 1a, the individual PU compositions are indicated by the letter M followed

by their elastic moduli in MPa. Heterogeneous composites with deliberate local stiffness are prepared by solvent-welding individual films with different levels of reinforcements into one

single component, as schematically illustrated in Fig. 1b. In the solvent-welding process, two film surfaces are first wetted by a good solvent and pressed together to allow for polymer

entanglement, which is then preserved upon solvent evaporation. Such entanglement eliminates the interfaces between individual films, leading to heterogeneous composites with efficient

stress transfer throughout the structure. The upper limit in elastic modulus achieved with the hierarchical polymer-based composite (7 GPa) can be further increased on the surface through

the deposition of a 100 nm-thick layer of Al2O3 via atomic layer deposition (150 °C per 160 min)36. Using this approach, we obtained 2 mm-thick heterogeneous composites with an out-of-plane

gradient in elastic modulus spanning over five orders of magnitude (Fig. 1c). The resulting composite is locally stiffer than tooth enamel on one side (_E__l_~102 GPa), whereas being softer

than skin on the other (_E__l_~1–5 MPa, see Fig. 1d). The extreme span in stiffness achievable within a single material free of macroscopic interfaces is far greater than that of other

artificial graded composites32 and is comparable to that of highly graded biological materials20. This opens numerous possibilities for the design of synthetic heterogeneous composites with

deliberate local mechanics. For instance, modular patches with any predefined _E__l_-profile can be solvent-welded at different preselected locations on the surface of a polymer substrate to

create 3D composites with tunable elastic modulus profiles in the in-plane and out-of-plane directions (Fig. 1e). In this example, not only the internal microstructure but also the shape of

the composite is designed to effectively fulfil a mechanical function, alike the design strategy of many biological materials. The out-of-plane _E__l_-profile is determined by the local

concentration of reinforcing elements throughout the cross-section of each modular patch at the microscale. The in-plane _E__l_-profile is controlled by the geometry and average elastic

moduli of the patches and of the underlying substrate at the macroscale (Fig. 1g and Supplementary Methods). All these parameters can be varied independently and in a modular fashion,

providing a wide design space for tailoring the local elastic moduli of the heterogeneous composite in both the in-plane and out-of-plane directions. FINITE ELEMENT ANALYSIS OF COMPOSITE

ARCHITECTURES To further explore the unusual set of properties offered by 3D heterogeneous composites with tailored _E__l_ profiles, we investigated specific architectures that would combine

high global stretchability with minimum local strains at specific surface sites. The response of 3D composites with deliberate _E__l_ profiles to stretching is first evaluated by simulating

the local mechanical stresses and strains across representative patch–substrate modules using finite element analysis (FEA) (Fig. 2). Each module consists of a prismatic patch with designed

_E__l_ profile deposited onto a ribbon of stretchable substrate. Four different patch–substrate module designs were investigated: two with a constant _E__l_ across the patch, one with a

graded _E__l_ profile, and one control module with patch and substrate of same elastic modulus. These different hypothetical arrangements are shown in Fig. 2a and referred to throughout the

text using the letter S followed by the elastic modulus of the patch (except for the graded patch, which is named S-Grad). FEA revealed that patches respond differently to the external

tensile strain, depending on whether their average elastic moduli (_Ē_pat) are equal or higher than that of the underlying substrate (_E_sub). For _Ē_pat > _E_sub, patches undergo

significant inward bending during tensile stretching of the representative modules. This effect generates compressive (negative) strains on the patch surface and tensile (positive) strains

across the substrate, as shown in Fig. 2c. In contrast, the patch exhibiting the same elastic modulus as the substrate (_Ē_pat = _E_sub, S-0040) experiences a combination of bending and

stretching. This leads to curved surfaces at the edge of the patch and a stretched area with high tensile strains at its centre (Fig. 2b and Supplementary Fig. S1). Among the patches with

_Ē_pat > _E_sub, we observe that bending becomes less pronounced as the average stiffness of the patch increases (higher _Ē_pat). The radius of curvature of the region that underwent

bending was found to be 9.7, 17.2 and 63.2 mm for the specimens S-0550, S-Grad and S-7000, respectively. As a result, the stiffest patch (S-7000) offers the advantage of a lower compressive

strain on the top surface and a lower tensile strain at the bottom of the underlying substrate (Fig. 2d). Because of its stiff top layer, the graded patch (S-Grad) experiences surface

compressive strains nearly as low as that of the stiffest patch (S-7000). In addition to the strains at the surface, the elastic modulus profile of the patch also affects the mechanical

stability and stretchability of the module, as local mismatches in _E__l_ may cause excessive stress concentrations within the structure and thus premature failure of the composite upon

stretching. Analysis of the stress distribution throughout the cross-section of the simulated modules revealed the expected stress peaks at regions where the elastic modulus changes abruptly

(Fig. 2d). Although the stress and strain indicated in Fig. 2d refer only to the normal values at the centre of the patch, similar trends were observed for the shear values at the edge of

the simulated patches (see Supplementary Fig. S2). The less abrupt changes in local elastic modulus throughout the architectures S-0550 and S-Grad lead to lower tensile stress peaks and thus

a presumably higher resistance against local delamination during stretching. Because of its graded architecture, the module S-Grad better distributes the stress along the height of the

patch, which contrasts to the sharp stress peak observed at the bottom of the stiffest homogeneous patch (S-7000, _z_=_z_int). Overall, the FEA indicate that the graded architecture is the

most suited to minimize the strain on the patch surface, whereas preventing premature failure of the stretched composites through reduced mechanical mismatches throughout the structure.

COMBINING ULTRA-STRETCHABILITY WITH LOCAL SURFACE STIFFNESS To experimentally investigate the surface strains and the failure resistance of composites exhibiting architecture similar to the

S-Grad design, we fabricated graded modules using the hierarchical reinforcement approach described above (E-Grad, Fig. 3). A highly stretchable, fully recoverable elastomeric substrate

(Fig. 3a) was produced by performing a two-step polymerization reaction of a 50:50 weight ratio mixture of hard and soft monomers in _N,N_-dimethylformamide (DMF), followed by casting in a

silicone rubber mould (see details in the Supplementary Methods). Mechanically graded patches were formed by solvent welding and hot pressing individual layers with progressively higher

elastic modulus using DMF as solvent. The elastic modulus was tuned to gradually increase from the bottom to the top of the patch by changing the type and concentration of reinforcing

elements, as depicted in Fig. 3b. A freeze-fractured cross-section of the resulting graded sample exhibits a very smooth surface across the platelet-free PU layers and no detectable

interface between the platelet-reinforced layers (Fig. 3c). This suggests that the macromolecules of the different original layers are effectively entangled and that a graded structure

containing an interpenetrating polymer matrix was successfully created. The effectiveness of the entangled polymeric matrix and the elastic modulus gradient in increasing the composite

failure resistance was investigated by performing tensile tests on graded (E-Grad) and non-graded (E-7000) experimental samples prepared as described above. Remarkably, substrates containing

the graded patch could be stretched by as much as 350% without failure due to localized internal stresses (Fig. 4a). The high shear stresses developed at the interface between the substrate

and the graded patch close to the patch edge (see Supplementary Fig. S2c) lead to partial detachment of the substrate for global tensile strains >150% (see white arrow in Fig. 4b).

However, because of the lower stresses developed within the graded patch as compared with the non-graded stiff patch (S-Grad and S-7000 in Supplementary Fig. S2), this partial detachment is

limited to the edge of the graded patch and does not lead to complete delamination of the patch–substrate interface (Fig. 4b and Supplementary Fig. S3). Instead, failure of the

patch–substrate module typically occurs through the rupture of the elastomeric substrate material close to the patch edge at global strains >350% without delamination (Supplementary Fig.

S4). This indicates that mechanical degradation in this system is controlled by the tensile strength of the substrate material rather than the strength of the patch–substrate interface,

which allows us to take full advantage of the high stretchability of the elastomeric substrate. In contrast, composites exhibiting a homogeneous patch of the stiffest material (E-7000)

delaminated completely at the interface between the patch and the substrate at strains between 150 and 200%. These results qualitatively agree with the FEA and can be explained by the lower

stress concentration at the patch–substrate interface predicted for the graded composite (Fig. 2d). Tensile mechanical tests were conducted to experimentally assess the local strain on the

surface of graded (E-Grad) and non-graded (E-0040) patches as a function of increasing global deformations. The local strain was obtained by measuring the length of the patch on lateral

images acquired by a travelling microscope during mechanical deformation (Fig. 4b). In line with the FEA predictions, local strains <1% were detected on the surface of the graded patch

for global strains as high as 300%. Conversely, samples consisting of both patch and substrate made of the same PU (E-0040, _Ē_pat = _E_sub) displayed the predicted steady increase in local

tensile strain for increasing global strains (Fig. 4c and inset of Fig. 2d). The inward bending effect observed in the simulation of the graded composite was confirmed by lateral recording

of the specimen during the tensile test (Fig. 4b). Interestingly, the as-prepared graded patch developed an outward curvature after solvent welding and hot pressing the individual composite

layers. This initial outward bending presumably results from the higher shrinkage of the substrate and the softer bottom layers of the graded patch upon removal of the welding solvent and

release of the load applied during hot pressing. GRADED COMPOSITES FOR STRETCHABLE ELECTRONICS To demonstrate the potential of such 3D-graded composites in combining unusual functional

properties, we deposited a 50-nm conductive gold layer on the top surface of the graded patch and measured its electrical response while stretching the underlying elastomeric substrate (Fig.

5a). Because of its small thickness and poor interfacial adhesion, the gold layer is expected to start deforming and to exhibit increasing electrical resistance at tensile strains of about

1%27; thus, much earlier than its strain-at-rupture of 20–30%27,37. As the strain of 1% is comparable to the failure tensile strain of high-performance semiconductor and dielectric layers

(for example indium–gallium–zinc oxide and aluminium oxide)4, the electrical response of the gold layer can be taken as a simple indicator of the effectiveness of the graded composites in

protecting brittle electronic devices in stretchable electronic applications. The stretching experiments revealed that the 3D graded composite can be globally strained by as much as 200%

without any detectable increase in the electrical resistance of the gold layer (Fig. 5a). This is in strong contrast with the sharp increase in resistance at ~1–2% strain obtained for a

control sample consisting of a gold layer deposited directly on the elastomeric substrate. The protection of brittle electronic devices over prolonged periods of time requires substrates

that are not only highly stretchable but that can also withstand extensive cyclic deformation. The resistance of the proposed 3D graded composites against cyclic strains was probed by

following the electrical resistance of the conductive gold layer while subjecting the underlying elastomeric substrate to a cyclic triangular strain pattern with maximum engineering strain

of 80%. In contrast to the sharp increase in resistivity observed in the first stretching cycle of a control sample, the 3D-graded composite was able to keep the gold layer fully conductive

and with no detectable increase in electrical resistance after more than 10 full cycles (Fig. 5b). The ability of the 3D-graded architecture to protect brittle electronic devices was

ultimately probed by assembling a light-emitting diode (LED) on the surface of a graded patch and testing its function while increasing tensile strains was applied to the substrate beneath.

By using silver paste, the diode was electrically contacted to two sputtered gold layers connected to a 9V external battery and finally fixed in place with epoxy glue. Upon stretching of the

whole construct, the switched-on LED deposited on the graded patch remained functional up to 150% global strain, as opposed to the impaired functionality and delamination observed for

control diodes assembled directly onto the elastomeric substrate (Fig. 5c). DISCUSSION Although elegant photolithographic approaches have been successful in locally increasing the elastic

modulus of polydimethylsiloxane elastomers within the MPa range by a factor of 5 (refs 25,38), the 100-fold reduction in the local-to-global strain ratio enabled by the graded architecture

outperforms previous attempts to obtain locally stiff islands that protect brittle inorganic layers from failure in stretchable electronics25,26,27,28,29. As the step at the patch edges

might be undesired in flexible electronics, other geometries can be readily obtained using other approaches to assemble the PU compositions with different level of reinforcement, including

hot-pressing, tape-casting, screen-printing and 3D rapid prototyping techniques. As an illustrative example, we produced a planar substrate with locally reinforced islands by simply

hot-pressing graded patches into an elastomeric thick layer (Supplementary Fig. S5). The step between the pressed patch and the elastomeric substrate is <15.2 μm, which enables sputtering

of conductive metallic interconnectors between LEDs assembled onto adjacent islands (Supplementary Figure S6). Using this flat configuration, in-plane gradients at the edge of the patch can

potentially be also introduced using individual layers of different sizes to eliminate the stress concentration leading to partial detachment of the substrate at the patch edge (Fig. 4b and

Supplementary Fig. S3). In addition to the macroscopic LEDs shown in Fig. 5c, our recent demonstration that high-performance thin film transistors can be deposited and successfully operated

on the surface of platelet-reinforced polymeric substrates26 confirms the great potential of using such graded, hierarchical composites in stretchable electronics and other functional

devices requiring extreme gradients in elastic modulus, including flexible solar cells, circuit boards, biological sensors and wearable electronic devices. The proposed methodology could be

further improved by exploring approaches to increase the thickness and the smoothness of the purely inorganic layer deposited on the hard side of the reinforced composite. In summary, we

show that tuning of the local reinforcement level of a thermoplastic elastomer in 3D can lead to polymer-based heterogeneous composites with unique set of mechanical properties within the

same material, including for example millimetre-thick profiled sheets with an out-of-plane soft-to-hard transition spanning 2 decades in elastic modulus combined with a global in-plane

stretchability >350%. Such properties are achieved by reinforcing the soft elastomeric polymer matrix with hard molecular domains, nanoplatelets and microplatelets at progressively higher

hierarchical levels and at deliberate positions of the composite. Spatial control over the reinforcement level is possible by solvent welding individual layers with different concentrations

of reinforcing elements. Our ability to create heterogeneous composites with locally tunable elastic modulus spanning over five orders of magnitude with a fully entangled polymer phase

allows us to combine unusual functional properties that would not be achievable with homogeneous materials. In addition to the locally stiff and globally stretchable substrates demonstrated

here, this method can potentially be explored to produce artificial biomaterials with extreme mechanical gradients for cartilage, tendon and ligament repair in regenerative medicine, durable

dental restorations that more closely match the flaw-tolerant architecture of natural tooth, and tougher graded adhesives that would reduce catastrophic failure of current fiber-reinforced

composites. The approach may also be exploited to create bioinspired heterogeneous architectures that mimic the structural features of biological materials, allowing for the investigation of

biological structure–function relationships of interest for reverse biomimetics39. METHODS MATERIALS All chemicals were purchased from Aldrich Co. and were of analytical grade, unless

otherwise stated. DMF (dried over molecular sieves), 4,4′-methylenebis(cyclohexyl isocyanate) (H-MDI, 90%), 1,4-butanediol (BDO,≥99%); poly(tetrahydrofuran) (T1000, _M_w=1,000 g mol−1),

glycerol ethoxylate (EG, _M_w=1,000 g mol−1) and dibutyltin dilaurate were used for the synthesis of PUs with different HS:SS ratios. Composites were prepared using a commercial

thermoplastic PU (Elastollan C64D, BASF, Germany), DMF (ACS grade), polyvinylpyrrolidone (PVP, _M_w=40,000 g mol−1), alumina platelets with average diameter of 7.5 μm and thickness of 200 nm

(Alusion, Antaria Limited, Australia) and laponite platelets with diameter of 25 nm and thickness of 1 nm (Laponite RD, ProChem, Switzerland). PU SYNTHESES PU syntheses were carried out

under nitrogen atmosphere in a three-neck round-bottom flask equipped with a reflux condenser. H-MDI and BDO were used as hard segments, T1000 as soft segment and EG as cross-linker. The

HS:SS ratio was adjusted by changing the proportion between T1000 and BDO. First, the glassware was dried with a heating gun at 350 °C to remove any adsorbed water. Then, a prepolymer was

prepared by loading the flask with H-MDI followed by the dropwise addition of a solution of T1000 and EG in DMF under magnetic stirring (600 r.p.m). The resulting mixture was kept at 80 °C

for 3 h. After formation of the prepolymer, the temperature was reduced to 60 °C and a solution of BDO in DMF was added to the flask to proceed with the polymerization reaction for a time

period of 1 h. Finally, dibutyltin dilaurate was added and stirred for additional 30 min. The reactant concentrations were adjusted to keep a constant NCO:OH molar ratio of 1:1 with a 5 wt%

excess of H-MDI. The final concentration of PU in DMF was 0.2 g ml−1. Polymer films were obtained by casting the solution onto silicone moulds and dried at 60 °C for 24 h. Supplementary

Table S1 summarizes the amounts of chemicals used for the PU syntheses. PREPARATION OF PU-BASED COMPOSITES Composites reinforced with nano- and microplatelets were prepared following the

procedure previously described by Libanori _et al_.34 In summary, alumina platelets were first dispersed in a solution of PVP in DMF and kept under stirring for 12 h. Next, PU pellets

(Elastollan) and a suspension of laponite in DMF (obtained through solvent exchange method)34,35 were added to the alumina/PVP suspension. The resulting mixture was kept at room temperature

and under stirring (600 r.p.m) until the polymer pellets were dissolved. The viscosity of the mixture was adjusted by removing DMF in an evaporator at 10 mbar and 60 °C (R-215 Rotavapor,

Buchi, Switzerland) before casting the fluid on polyethylene plates using a doctor blade (height=1 mm). The remaining DMF was removed by placing the sample in a conventional oven (Memmert,

UNE 200, Germany) at 60 °C for 24 h. The obtained composites were finally annealed at 130 °C for 3 h. Supplementary Table S2 depicts the composition of the platelet-reinforced composites

investigated in this study. PREPARATION OF PATCH–SUBSTRATE COMPOSITES Patch–substrate modules for mechanical and electrical testing were prepared by first assembling individual films (M0550,

M1600, M3600 and M7000) into multilayered 0.4 × 5 cm2 ribbons using the solvent-welding technique. For that purpose, a small amount of DMF was first applied on the two surfaces to be welded

using a cotton swab. Pressure was manually applied onto the multilayer stack by squeezing the sample in between glass slides. The patch layers were assembled from the hardest to the softest

material and subsequently welded onto a 5 cm × 5 cm × 0.19 mm M0040 substrate. The composition and thickness of each individual layer is indicated in Supplementary Table S3. Finally, the

samples were dried at 60 °C for 12 h in a vacuum oven. Two millimeter-wide dogbone samples were cut from the large M0040 substrate in the direction perpendicular to the multilayered ribbon

to obtain patch–substrate modules with the architecture shown in Fig. 2a–c. For the resistance measurements, a 50 nm-thick gold layer was sputtered on the top of the stiffest layer

(Supplementary Fig. S7). Sputtering was carried out using a working distance of 50 mm, current of 40 mA and pressure of 2 × 10−5 mbar for 200 s. Electrical contacts were made by gluing 100

μm-diameter copper wires to the gold layer using silver paste and an epoxy resin. PREPARATION OF 3D HETEROGENEOUS COMPOSITE The 3D heterogeneous composite shown in Fig. 1f was prepared by

first solvent welding 5 × 5 cm2 individual layers of the compositions M0550, M1600, M3600, M7000, as described above. The resulting multilayered welded film was cut into 5 × 5 mm2 patches

using a scalpel. Finally, the patches were welded onto a 190 μm-thick M0040 substrate by applying DMF on both surfaces and manually pressing them together using glass slides. Patches welded

on the top of the substrate were locally heated (60 °C) with a heating gun to ensure good adhesion between the materials and to remove the remaining solvent. CHARACTERIZATION For a detailed

description of the experimental techniques used throughout this work, please refer to the Supplementary Methods. ADDITIONAL INFORMATION HOW TO CITE THIS ARTICLE: Libanori, R. _et al_.

Stretchable heterogeneous composites with extreme mechanical gradients. _Nat. Commun._ 3:1265 doi: 10.1038/ncomms2281 (2012). REFERENCES * Ramaniraka N. A., Rakotomanana L. R., Leyvraz P. F.

The fixation of the cemented femoral component - effects of stem stiffness, cement thickness and roughness of the cement-bone surface. _J. Bone Joint Surg. Br._ 82B, 297–303 (2000). Google

Scholar * Prenleloup A., Gmur T., Botsis J., Papailiou K. O., Obrist K. Stress and failure analysis of crimped metal-composite joints used in electrical insulators subjected to bending.

_Compos. Part A Appl. Sci. Manuf._ 40, 644–652 (2009). Article Google Scholar * Romilly D. P., Clark R. J. Elastic analysis of hybrid bonded joints and bonded composite repairs. _Compos.

Struct._ 82, 563–576 (2008). Article Google Scholar * Cherenack K. H., Munzenrieder N. S., Troster G. Impact of mechanical bending on ZnO and IGZO thin-film transistors. _Ieee Electron

Dev. Lett._ 31, 1254–1256 (2010). Article CAS Google Scholar * Mortensen A., Suresh S. Functionally graded metals and metal-ceramic composites.1. Processing. _Int. Mater. Rev._ 40,

239–265 (1995). Article CAS Google Scholar * Tilbrook M. T., Moon R. J., Hoffman M. Crack propagation in graded composites. _Compos. Sci. Technol._ 65, 201–220 (2005). Article Google

Scholar * Miserez A., Schneberk T., Sun C. J., Zok F. W., Waite J. H. The transition from stiff to compliant materials in squid beaks. _Science_ 319, 1816–1819 (2008). Article CAS ADS

Google Scholar * Maas M. C., Dumont E. R. Built to last: the structure, function, and evolution of primate dental enamel. _Evol. Anthropol._ 8, 133–152 (1999). Article Google Scholar *

Bruet B. J. F., Song J. H., Boyce M. C., Ortiz C. Materials design principles of ancient fish armour. _Nat. Mater._ 7, 748–756 (2008). Article CAS ADS Google Scholar * Yao H. M. et al.

Protection mechanisms of the iron-plated armor of a deep-sea hydrothermal vent gastropod. _Proc. Natl Acad. Sci. USA_ 107, 987–992 (2010). Article CAS ADS Google Scholar * Dunlop J. W.

C., Fratzl P. _Annu Rev Mater Res_ 40, 1–24 (2010). Article CAS ADS Google Scholar * Bentov S. et al. Enamel-like apatite crown covering amorphous mineral in a crayfish mandible. _Nat.

Commun._ 3, 839 (2012). Article Google Scholar * Chai H., Lee J. J. W., Constantino P. J., Lucas P. W., Lawn B. R. Remarkable resilience of teeth. _Proc. Natl Acad. Sci. USA_ 106,

7289–7293 (2009). Article CAS ADS Google Scholar * Waite J. H., Vaccaro E., Sun C. J., Lucas J. M. Elastomeric gradients: a hedge against stress concentration in marine holdfasts?

_Philos. Trans. R. Soc. Lond. B Biol. Sci._ 357, 143–153 (2002). Article CAS Google Scholar * Jager I., Fratzl P. Mineralized collagen fibrils: a mechanical model with a staggered

arrangement of mineral particles. _Biophys. J._ 79, 1737–1746 (2000). Article CAS ADS Google Scholar * Seidi A., Ramalingam M., Elloumi-Hannachi I., Ostrovidov S., Khademhosseini A.

Gradient biomaterials for soft-to-hard interface tissue engineering. _Acta Biomater._ 7, 1441–1451 (2011). Article CAS Google Scholar * Thomopoulos S., Williams G. R., Gimbel J. A.,

Favata M., Soslowsky L. J. Variation of biomechanical, structural, and compositional properties along the tendon to bone insertion site. _J. Orthop. Res._ 21, 413–419 (2003). Article Google

Scholar * Imbeni V., Kruzic J. J., Marshall G. W., Marshall S. J., Ritchie R. O. The dentin-enamel junction and the fracture of human teeth. _Nat. Mater._ 4, 229–232 (2005). Article CAS

ADS Google Scholar * Harrington M. J., Masic A., Holten-Andersen N., Waite J. H., Fratzl P. Iron-clad fibers: a metal-based biological strategy for hard flexible coatings. _Science_ 328,

216–220 (2010). Article CAS ADS Google Scholar * Vincent J. F. V., Wegst U. G. K. Design and mechanical properties of insect cuticle. _Arthropod. Struc. Dev._ 33, 187–199 (2004). Article

Google Scholar * Buehler M. J. Tu(r)ning weakness to strength. _Nano Today_ 5, 379–383 (2010). Article CAS Google Scholar * Fratzl P. Biomimetic materials research: what can we really

learn from nature's structural materials? _J. R Soc. Interface_ 4, 637–642 (2007). Article CAS Google Scholar * Huang M., Wang R., Thompson V., Rekow D., Soboyejo W. O. Bioinspired

design of dental multilayers. _J. Mater. Sci. Mater. Med._ 18, 57–64 (2007). Article CAS Google Scholar * Kim D. H., Xiao J. L., Song J. Z., Huang Y. G., Rogers J. A. Stretchable,

curvilinear electronics based on inorganic materials. _Adv. Mater._ 22, 2108–2124 (2010). Article CAS Google Scholar * Cotton D. P. J., Popel A., Graz I. M., Lacour S. P. Photopatterning

the mechanical properties of polydimethylsiloxane films. _J. Appl. Phys._ 109, 054905 (2011). Article ADS Google Scholar * Erb R. M. et al. Locally reinforced polymer-based composites for

elastic electronics. _ACS Appl. Mater. Interface_ 4, 2860–2864 (2012). Article CAS Google Scholar * Lacour S. P., Wagner S., Huang Z. Y., Suo Z. Stretchable gold conductors on

elastomeric substrates. _Appl. Phys. Lett._ 82, 2404–2406 (2003). Article CAS ADS Google Scholar * Kim D. H. et al. Epidermal electronics. _Science_ 333, 838–843 (2011). Article CAS

ADS Google Scholar * Lacour S. P., Chan D., Wagner S., Li T., Suo Z. G. Mechanisms of reversible stretchability of thin metal films on elastomeric substrates. _Appl. Phys. Lett._ 88,

(2006). * Baroud G., Nemes J., Heini P., Steffen T. Load shift of the intervertebral disc after a vertebroplasty: a finite-element study. _Eur. Spine J._ 12, 421–426 (2003). Article CAS

Google Scholar * Smith L., Xia Y. N., Galatz L. M., Genin G. M., Thomopoulos S. Tissue-engineering strategies for the tendon/ligament-to-bone insertion. _Connect. Tissue Res._ 53, 95–105

(2012). Article CAS Google Scholar * Li X. R. et al. Nanofiber scaffolds with gradations in mineral content for mimicking the tendon-to-bone insertion site. _Nano Lett._ 9, 2763–2768

(2009). Article ADS Google Scholar * Phillips J. E., Burns K. L., Le Doux J. M., Guldberg R. E., Garcia A. J. Engineering graded tissue interfaces. _Proc. Natl Acad. Sci. USA_ 105,

12170–12175 (2008). Article CAS ADS Google Scholar * Libanori R., Munch F. H. L., Montenegro D. M., Studart A. R. Hierarchical reinforcement of polyurethane-based composites with

inorganic micro- and nanoplatelets. _Composites Sci. Technol._ 72, 435–445 (2012). Article CAS Google Scholar * Liff S. M., Kumar N., McKinley G. H. High-performance elastomeric

nanocomposites via solvent-exchange processing. _Nat. Mater._ 6, 76–83 (2007). Article CAS ADS Google Scholar * Lee S. M. et al. Greatly increased toughness of infiltrated spider silk.

_Science_ 324, 488–492 (2009). Article CAS ADS Google Scholar * Lohmiller J., Woo N. C., Spolenak R. Microstructure-property relationship in highly ductile Au-Cu thin films for flexible

electronics. _Mater. Sci. Eng. A Struct. Mater._ 527, 7731–7740 (2010). Article Google Scholar * Graz I. M., Cotton D. P. J., Robinson A., Lacour S. P. Silicone substrate with _in situ_

strain relief for stretchable thin-film transistors. _Appl. Phys. Lett._ 98,, 124101 (2011). * Studart A. R. Towards High-Performance Bioinspired Composites. _Adv. Mater._ 24, 5024–5044

(2012). Article CAS Google Scholar Download references ACKNOWLEDGEMENTS We thank Niko Münzenrieder, Thomas Kinkeldei and Emilio Gini for the experimental support; Professor Gerhard

Tröster, Dr Kunigunde Cherenack and Dr Davide Carnelli for fruitful discussions; and BASF (Germany), Antaria Limited (Australia) and ProChem (Switzerland) for kindly supplying some of the

materials used in this study. AUTHOR INFORMATION AUTHORS AND AFFILIATIONS * Department of Materials, Complex Materials, ETH Zurich, Zurich, 8093, Switzerland Rafael Libanori, Randall M. Erb,

Alain Reiser, Hortense Le Ferrand & André R. Studart * Department of Materials, Laboratory for Nanometallurgy, ETH Zurich, Zurich, 8093, Switzerland Martin J. Süess & Ralph Spolenak

Authors * Rafael Libanori View author publications You can also search for this author inPubMed Google Scholar * Randall M. Erb View author publications You can also search for this author

inPubMed Google Scholar * Alain Reiser View author publications You can also search for this author inPubMed Google Scholar * Hortense Le Ferrand View author publications You can also search

for this author inPubMed Google Scholar * Martin J. Süess View author publications You can also search for this author inPubMed Google Scholar * Ralph Spolenak View author publications You

can also search for this author inPubMed Google Scholar * André R. Studart View author publications You can also search for this author inPubMed Google Scholar CONTRIBUTIONS A.R.S. conceived

the study. A.R., H.L.F. and R.L. synthesized the materials and performed mechanical tests. R.L. and M.J.S. designed and performed finite element analysis. R.L., A.R. and R.M.E. performed

electrical response measurements. R.L. and R.M.E. integrated electrical components onto the flexible substrates. All authors contributed extensively to the data analysis and discussion.

A.R.S. wrote the paper. A.R.S. and R.L. wrote the Supplementary Information. R.L., R.S. and A.R.S. critically revised the manuscript. CORRESPONDING AUTHOR Correspondence to André R. Studart.

ETHICS DECLARATIONS COMPETING INTERESTS The authors declare no competing financial interests. SUPPLEMENTARY INFORMATION SUPPLEMENTARY INFORMATION Supplementary Figures S1-S12, Supplementary

Tables S1-S5, Supplementary Methods and Supplementary References (PDF 1936 kb) RIGHTS AND PERMISSIONS Reprints and permissions ABOUT THIS ARTICLE CITE THIS ARTICLE Libanori, R., Erb, R.,

Reiser, A. _et al._ Stretchable heterogeneous composites with extreme mechanical gradients. _Nat Commun_ 3, 1265 (2012). https://doi.org/10.1038/ncomms2281 Download citation * Received: 18

July 2012 * Accepted: 12 November 2012 * Published: 11 December 2012 * DOI: https://doi.org/10.1038/ncomms2281 SHARE THIS ARTICLE Anyone you share the following link with will be able to

read this content: Get shareable link Sorry, a shareable link is not currently available for this article. Copy to clipboard Provided by the Springer Nature SharedIt content-sharing

initiative