- Select a language for the TTS:

- UK English Female

- UK English Male

- US English Female

- US English Male

- Australian Female

- Australian Male

- Language selected: (auto detect) - EN

Play all audios:

28 MARCH 1997 ------------------------- A SQUARE ROUTE TO BALES ADDS UP TO SATISFACTION SQUARE BALES ARE NOT EVERYONES FIRST CHOICE. SOME WHO HAVE TRIED THEM HAVE SWITCHED BACK TO ROUND

ONES, BUT MICHAEL WILLIAMS DISCOVERED A GLOUCESTERSHIRE DAIRY FARM WHERE SQUARE BALES ARE TAKING OVER MOST of the silage on Geoff Newtons 300-acre Staverton Court Farm at Staverton, near

Cheltenham goes into the clamp, but about 30% is baled. Last year this amounted to some 600 wrapped bales for the farms 150 head of cattle. In previous years the vast majority of bales were

round, but when Mr Newton decided to try a small scale switch to square bales to see how they compared, the results were encouraging to the point that about 90% of last years silage bales

were square. Which leaves 50-60 round bales for feeding out in the field – the only situation where square bales are considered to be less convenient. "This is a dry area, and we

usually feed some silage in the field during the winter," he says. "We use an Econ unroller for the round bales which works very well. "If we wanted to feed square bales in

the field we would need two people, one to drive the tractor and the other to fork the silage off a trailer. The alternative would be to put a complete bale into a feeder, but that is not

ideal because of the way the ground gets badly poached around the feeder." Mr Newton maintains it is generally the square bales which are easier to handle. "If you have one or two

cattle to feed in a pen or a loose box there is simply no comparison, the square bales are much easier to use," he says. The big advantage of square bale silage is the way the bale

breaks down into individual bundles or wafers which can be picked up manually or with a pitch fork. This is handy when silage is being used against a feed barrier as it is a simple job to

remove the wrapping, cut the strings and spread bundles of silage along the length of the barrier. "Round bales are completely different, and if there is not enough space to unroll one

they can be very awkward to deal with." Wrapped square bales are loaded and stacked with a modified Howard bale gripper attachment on a telescopic handler. The gripper was made to

handle 1.2m (4ft) cross-section Howard bales, but Mr Newton narrowed the gap between the arms to suit the smaller Hesston bales. It handles the bales either individually or in twos to get

extra height for stacking, and improved utilisation of storage space is one of the advantages of the switch from round bales. Hydraulically powered, squeezing gripper arms put firm pressure

on the sides of the bales and reduce the risk of damaging the layers of wrapping film, but Mr Newton says damage can still occur. "You need to handle any wrapped bale – round or square

– very gently, and we still get some damage, even with the gripper. If the wrapping is damaged it is important to patch it up immediately. Fortunately, we have found very few damaged bales

this winter." Mr Newton relies on Philip Odam, who runs a contracting business based at Bishops Cleeve, to make and wrap the silage bales. Mr Odam runs two John Deere 550 round balers

and two Hesston 4750s for the square bales, and he wraps in the field using a Kverneland UN7655. Usual charge for baling and wrapping is £4.10p a bale – both round and square – with some

variation for distance and acreage. Bales are between 1.37m (4ft6in) and 1.42m (4ft8in) long, and this makes a package with about the same weight as a round silage bale. This means the same

number of bales an acre for both types, and the amount of wrapping film is also nearly the same. Most of Mr Odams customers have now tried square bale silage and the reaction has been good,

he says. Everyone liked the bales, although some have not yet found a satisfactory technique for handling them. "Farmers who tried square bale silage last year covered just about the

full spectrum of our customers from smallholdings to some of the biggest farms, and I dont think we have anyone who does not like the way the bales break up into bundles when the string is

cut," explains Mr Odam. "They really are easier to use than round bales." He also reports a favourable reaction to the way the bales stack. "Square bales always were

ideal for utilising space, and these bales need less room than round bales. We even have one customer who has sold some of his square silage bales off the farm, and he likes them because he

can get a better load on a lorry than he could with round bales." Some customers, he says, have also reported an improvement in silage quality in their square bales, and this could be

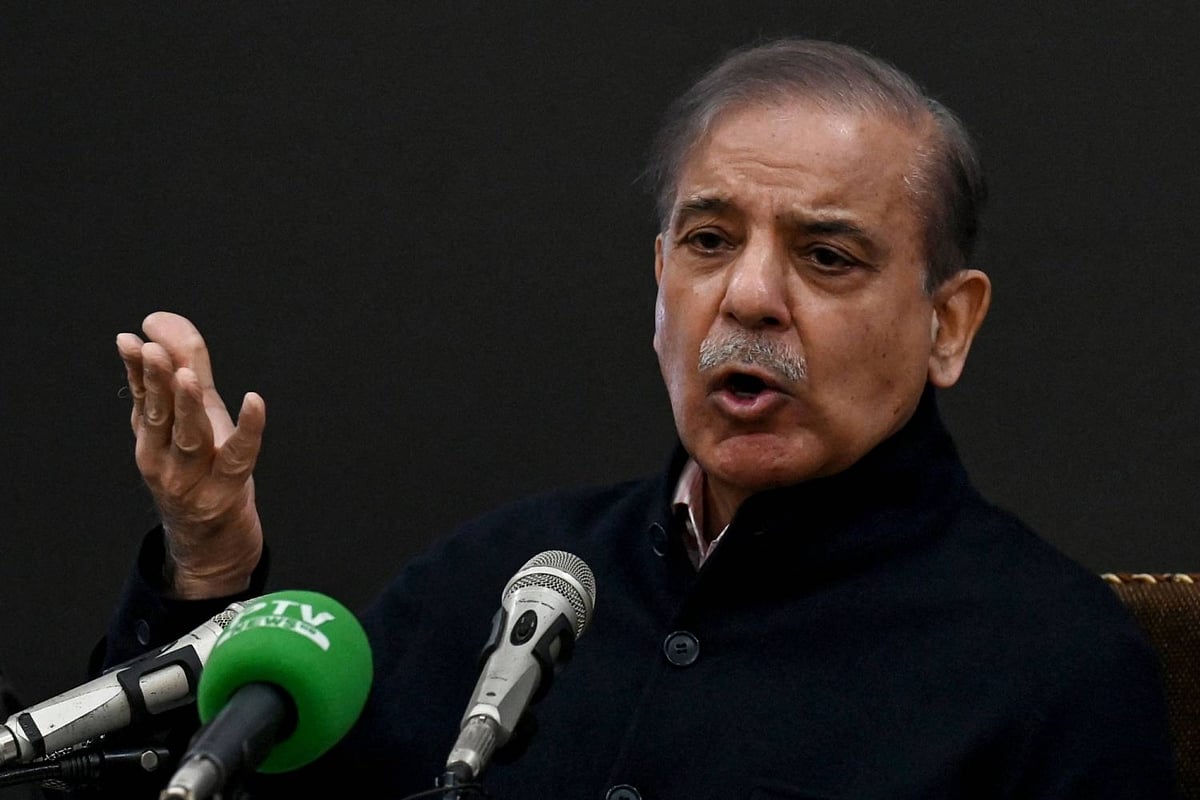

due to the more even bale density achieved by the pressure plate on a square baler. * _This modified Howard grab stacks the wrapped bales. Inset: Geoff Newton._ _Philip Odam uses

Hesston 4750 balers to pump out the square pack._ ------------------------- SQUARE BALE BONUS ------------------------- • Easier handling of wafer segments. • Better use of

storage space. • More on a trailer. But: • Round bales better suited to outdoor feeding.