- Select a language for the TTS:

- UK English Female

- UK English Male

- US English Female

- US English Male

- Australian Female

- Australian Male

- Language selected: (auto detect) - EN

Play all audios:

INDUSTRIAL CROPS AND PRODUCTS Volume 170, 15 October 2021, 113752 https://doi.org/10.1016/j.indcrop.2021.113752Get rights and content HIGHLIGHTS * • Pine needles lignocellulosic active paper

incorporated with nanozeolite was fabricated. * • The lignocellulosic paper showed improved water vapor transmission rate. * • The lignocellulosic paper showed high ethylene scavenging

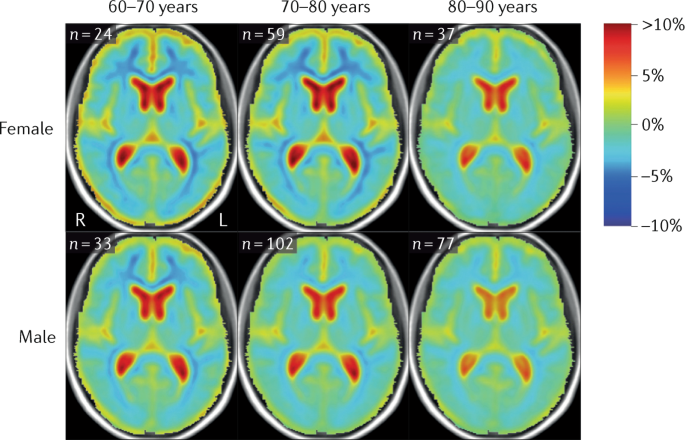

properties. * • Active pine needle based paper suitable for fresh produce active packaging. * • Studies indicated valorization of pine needles biomass into paper fabrication. ABSTRACT The

pines needle falls approximately 2–3 ha−1 year−1 on the forest floors resulting in a considerable amount of lignocellulosic biowaste. The present study aimed to develop pine needles based

lignocellulosic active paper and investigate the effect of 5, 20, and 30% (v/w) nano zeolite addition on the physical, mechanical, and microstructural property of the papers. The developed

papers were characterized by scanning electron microscope, transmission electron microscope, Fourier transform infrared spectrometer, and X-ray diffraction. As the zeolite concentration was

increased from 5% to 30% in the paper, enhanced water permeability was seen from 5.18 ± 0.34 - 3.88 ± 0.33 g/cm2/day (PN/ZL 30% paper). The addition of 5% zeolite increased the tensile and

burst strength from 19.53 ± 3.53 Nm/g and 3.63 ± 0.23 kg/cm2, respectively. The porosity was increased from 340 ± 20 to 1170 ± 60, and Cobb value increased from 338.3 ± 1.5- 406.7 ± 1.5

g/m2. The alterations in terms of surface microstructure in the paper with 20, 30% zeolite were noticed whereas XRD illustrated the high compatibility among the lignocellulosic network of

pines and zeolite. The pine needle paper with 30% zeolite possessed remarkable ethylene scavenging properties (62%), opening a way to valorize pine needle waste for food packaging

application. GRAPHICAL ABSTRACT INTRODUCTION There has been a significant surge in research on active and environmentally friendly food packaging in recent times (Janjarasskul and Suppakul,

2018). Active packaging such as ethylene scavengers is presently among the most rising technologies used to maintain the freshness of fruits and vegetables (Gaikwad et al., 2020a,b). The

impregnation of the ethylene scavenging agents in the packaging matrix instead of directly adding them into the package in sachet form can minimize the quantity of such scavenging agents

required and fulfill the increased demand of customers for safe and healthy food. Zeolites contain a 3-dimensional microporous structure of crystalline aluminosilicates with pore size

varying from 3 - 12 Å, which allows the absorption of several compounds, including ethylene gas, with some specificity (Gaikwad and Lee, 2017a,2017b). They use the properties of cation

exchange capacity, molecular sieving, and adsorption to eliminate ethylene gas (Suslow 1997). Natural zeolites showed ethylene adsorption capability between 1.3 to 19.6 mmol kg−1 (Keller et

al., 2013). For natural zeolites, a large pore diameter, i.e., 12 Å, favors ethylene gas to permit through the opening pore of zeolite and be absorbed inside the three-dimensional zeolite

structure. Some absorbents, including zeolite, are commercially available along with KMnO4 as the mixture of adsorbent with KMnO4 showed high ethylene scavenging capacity. However, KMnO4

should not be in direct food contact because of its toxicity, and hence the use of KMnO4 limits its application in food packaging (Gaikwad et al., 2020a,b). Only the impregnation of zeolites

into the polymeric structure has been studied as an incorporation technology for researchers' packaging applications (Awalgaonkar et al. 2020). The polymeric matrix includes

low-density polyethylene (LDPE) (Dirim et al. 2003), LDPE with styrene-ethylene-butylene-styrene (Monprasit et al., 2011), Cellulose (Sen and Das, 2017), and chitosan (do Nascimento Sousa et

al. 2020). The demand for environment-friendly packaging materials has considerably increased because of environmental concerns regarding the use of synthetic petroleum-based plastics

(Gaikwad et al., 2019a). Paper plays an important role in the packaging sector due to advantages that may arise in low costs, processability on the machine in the converting process,

biodegradability, lightweight, recycling, and best printing ability. Paper-based packaging materials are commonly used for food and beverage product packaging (Bumbudsanpharoke and Ko,

2018). Several research studies focused on increasing the performance of traditional lignocellulose-based papers; through processes of surface treatment or modification, typical paper-based

packaging material can be made into a functional packaging paper that can be utilized in active food packaging applications. Antibacterial wrapping paper incorporated with silver-zeolite for

raw meat packaging application (Lee et al., 2011). Pine forests are the major and are extensively spread in Northeast China, South Korea, Japan, and India's northern part, specifically

the main species with chir pine (_Pinus roxburghii_) (Bisht et al. 2014). The lignocellulose from pine needles contains 41% cellulose, which is equivalent to softwood (42%) (Chauhan et al.,

2018). Simultaneously, the lignin content is 35.1%, higher than softwood (Lal et al., 2013). Being high in lignin content, fallen needles remain undecomposed for a long time. Approximately

2–3 ha−1 year−1 pines needle falls on the forest floors (Tiwari et al. 2016). On the forest floor, the deep layer of dry pine needles is the main cause of forest fires yearly in India

(Sharma and Williams, 2009). The burning of pine needles results in the formation of volatiles hazardous to the environment (Safi et al., 2004). Therefore, proper usage of pine needles

requires much attention. Due to their high cellulosic content, pine needles are ideal for transformation into bio-based packaging material. None of the research studies has explored the

development and characterization of pine needle pulp-based active papers to the best of our knowledge. The present study aims to develop and characterize paper sheets from pine needles pulp

impregnated with nano zeolite in different proportions 0% 5%, 10%, 20%, and 30% (w/w) as an ethylene scavenging paper for active packaging applications. The detailed evaluation of physical,

mechanical properties and characterization was done to analyze the influence of zeolite on pine needle-based paper fiber and its sheet formation by using Fourier transformation infrared

spectroscopy (FTIR), Field-emission scanning electron microscopy (FE-SEM), Transmission electron microscope (TEM), X-ray diffraction (XRD), water vapor transmission rate (WVTR). Furthermore,

the developed active paper's ethylene scavenging capacity was studied, and results are presented and discussed. We proposed its utilization as a novel paper-based packaging,

particularly in fresh produce packaging applications. SECTION SNIPPETS MATERIALS Semi-dried pine needles were collected from the Indian Institute of Technology Roorkee, Saharanpur Campus,

Uttar Pradesh, India, Zeolite (Na86[(AlO2)86(SiO2)106]nH2O) in granular form was purchased from Vishuddh Systems (Mumbai, India) with pore diameter, bulk density, and beads size were 9 Å,

0.62 g/cm2, and 1.7-2.5 mm, respectively. The zeolite beads were converted into powder form using a ball mill (Retsch MM 400, Munich, Germany) for 5 hours and 40 minutes to increase the

surface area. PHYSICAL PROPERTIES OF THE ACTIVE PINE NEEDLE PAPER The formulated active pine needle paper sheets were evaluated for different physical properties as these are the critical

parameters for paper quality. The results for the physical properties of the active pine needle paper are shown in Table 1. CONCLUSION In the present study, pine needles valorization for the

development of sustainable lignocellulosic active packaging material is reported. The lignocellulosic active paper was fabricated using a pine needle pulp with varying nanozeolite 13X (0,

5, 10, 20, and 30%). Apart from physical and mechanical properties, the ethylene scavenging capacity of the active paper was also evaluated. An increase in the zeolite percentage resulted in

an enhancement in water vapor transmission rate and a slight CREDIT AUTHORSHIP CONTRIBUTION STATEMENT AVINASH KUMAR: Investigation, Formal analysis, Visualization, Writing - Original Draft.

VIDHI GUPTA: Writing - Original Draft, Formal analysis, Writing - Review & Editing, Revision of manuscript. SUMAN SINGH: Resources, Methodology, Data Curation, Validation. SHASHANK

SAINI: Experimental help, KIRTIRAJ K. GAIKWAD: Conceptualization, Methodology, Resources, Writing - Review & Editing, Revision of manuscript, Visualization, Supervision, Project

administration, Funding acquisition. DECLARATION OF COMPETING INTEREST The authors report no declarations of interest. ACKNOWLEDGMENTS Avinash Kumar would like to thank the Ministry of Human

Resources and Development (MHRD), Government of India, for providing financial support to carry out this research work. REFERENCES (50) * K. Bilba_ et al._ FOURIER TRANSFORM INFRARED

SPECTROSCOPIC STUDY OF THERMAL DEGRADATION OF SUGAR CANE BAGASSE JOURNAL OF ANALYTICAL AND APPLIED PYROLYSIS (1996) * N. Bumbudsanpharoke_ et al._ THE GREEN FABRICATION, CHARACTERIZATION,

AND EVALUATION OF CATALYTIC ANTIOXIDATION OF GOLD NANOPARTICLE-LIGNOCELLULOSE COMPOSITE PAPERS FOR ACTIVE PACKAGING INTERNATIONAL JOURNAL OF BIOLOGICAL MACROMOLECULES (2018) * R.S. Chutia_

et al._ THERMOGRAVIMETRIC AND DECOMPOSITION KINETIC STUDIES OF MESUA FERREA L. DEOILED CAKE BIORESOURCE TECHNOLOGY (2013) * S.D. do Nascimento Sousa_ et al._ ETHYLENE ADSORPTION ON

CHITOSAN/ZEOLITE COMPOSITE FILMS FOR PACKAGING APPLICATIONS FOOD PACKAGING AND SHELF LIFE (2020) * N. Patdhanagul_ et al._ COMBINED MODIFICATION OF ZEOLITE NAY BY PHENYL TRIMETHYL AMMONIUM

BROMIDE AND POTASSIUM FOR ETHYLENE GAS ADSORPTION MICROPOROUS AND MESOPOROUS MATERIALS (2012) * C.M. Popescu_ et al._ CHARACTERIZATION OF FUNGAL DEGRADED LIMEWOOD BY FT-IR AND 2D IR

CORRELATION SPECTROSCOPY MICROCHEMICAL JOURNAL (2010) * M.J. Safi_ et al._ "GLOBAL DEGRADATION KINETICS OF PINE NEEDLES IN AIR." THERMOCHIMICA ACTA (2004) * E. Alagbe_ et al._

PHYSICAL, CHEMICAL AND MECHANICAL PROPERTIES OF CORN SHEATH AS PULP AND PAPER RAW MATERIAL JOURNAL OF PHYSICS: CONFERENCE SERIES (2019) * M.O. Aremu_ et al._ SUITABILITY OF NIGERIAN CORN

HUSK AND PLANTAIN STALK FOR PULP AND PAPER PRODUCTION EUROPEAN SCIENTIFIC JOURNAL (2015) * G. Awalgaonkar_ et al._ ETHYLENE‐REMOVING PACKAGING: BASIS FOR DEVELOPMENT AND LATEST ADVANCES

COMPREHENSIVE REVIEWS IN FOOD SCIENCE AND FOOD SAFETY (2020) * A.S. Bisht_ et al._ PINE NEEDLES A SOURCE OF ENERGY FOR HIMALAYAN REGION INTERNATIONAL JOURNAL OF SCIENTIFIC & TECHNOLOGY

RESEARCH (2014) * J. de Bruijn_ et al._ USE OF A COPPER-AND ZINC-MODIFIED NATURAL ZEOLITE TO IMPROVE ETHYLENE REMOVAL AND POSTHARVEST QUALITY OF TOMATO FRUIT CRYSTALS (2020) * I. Bykov

CHARACTERIZATION OF NATURAL AND TECHNICAL LIGNINS USING FTIR SPECTROSCOPY DEPARTMENT OF CHEMICAL ENGINEERING AND GEOSCIENCES (2008) * L. Chauhan_ et al._ UTILIZATION OF PINE NEEDLES FOR

DEVELOPMENT OF BIO BASED PACKAGING MATERIAL INTERNATIONAL JOURNAL OF CURRENT MICROBIOLOGY AND APPLIED SCIENCES (2018) * A. Coloma_ et al._ DEVELOPMENT OF AN ACTIVE FILM WITH NATURAL ZEOLITE

AS ETHYLENE SCAVENGER JOURNAL OF THE CHILEAN CHEMICAL SOCIETY (2014) * L. Dai_ et al._ ROBUST GUAR GUM/CELLULOSE NANOFIBRILS MULTILAYER FILMS WITH GOOD BARRIER PROPERTIES ACS. APPL. MATER.

INTER. (2017) * E. Dinand_ et al._ MERCERIZATION OF PRIMARY WALL CELLULOSE AND ITS IMPLICATION FOR THE CONVERSION OF CELLULOSE I → CELLULOSE II CELLULOSE (2002) * S.N. Dirim_ et al._ A NEW

PROTECTIVE POLYETHYLENE BASED FILM CONTAINING ZEOLITES FOR THE PACKAGING OF FRUITS AND VEGETABLES: FILM PREPARATION TURKISH JOURNAL OF ENGINEERING AND ENVIRONMENTAL SCIENCES (2003) * K.K.

Gaikwad_ et al._ CURRENT SCENARIO OF GAS SCAVENGING SYSTEMS USED IN ACTIVE PACKAGING-A REVIEW KOREAN JOURNAL OF PACKAGING SCIENCE & TECHNOLOGY (2017) * K.K. Gaikwad_ et al._ CURRENT

SCENARIO OF GAS SCAVENGING SYSTEMS USED IN ACTIVE PACKAGING—A REVIEW KOREAN JOURNAL OF PACKAGING SCIENCE & TECHNOLOGY (2017) * K.K. Gaikwad_ et al._ MOISTURE ABSORBERS FOR FOOD PACKAGING

APPLICATIONS ENVIRONMENTAL CHEMISTRY LETTERS (2019) * K.K. Gaikwad_ et al._ HIGH ADSORPTION OF ETHYLENE BY ALKALI-TREATED HALLOYSITE NANOTUBES FOR FOOD-PACKAGING APPLICATIONS ENVIRONMENTAL

CHEMISTRY LETTERS (2018) * K.K. Gaikwad_ et al._ ETHYLENE SCAVENGERS FOR ACTIVE PACKAGING OF FRESH FOOD PRODUCE ENVIRONMENTAL CHEMISTRY LETTERS (2020) * K.K. Gaikwad_ et al._ ETHYLENE

SCAVENGERS FOR ACTIVE PACKAGING OF FRESH FOOD PRODUCE ENVIRONMENTAL CHEMISTRY LETTERS (2020) * T. Janjarasskul_ et al._ ACTIVE AND INTELLIGENT PACKAGING: THE INDICATION OF QUALITY AND SAFETY

CRITICAL REVIEWS IN FOOD SCIENCE AND NUTRITION (2018) View more references CITED BY (61) * CELLULOSIC PINE NEEDLES-BASED BIOREFINERY FOR A CIRCULAR BIOECONOMY 2023, Bioresource Technology

Show abstract Pine needles (PNs) are one of the largest bio-polymer produced worldwide. Its waste, i.e., fallen PNs, is mostly responsible for forest fires and is a major challenge. In

present article, we have reviewed differenteffortsmadeto tackle this situation. PNs have been used in various fields such asin composite, water purification industries,electronic devices,

etc. Gasification is one of the appealing processes for turning PNs into bio-energy; pyrolysis technique has been employed to create various carbon-based water purification materials;

saccharification combined with fermentation produced good yields of bio-ethanol; Pd or Ni/PNs biocatalyst showed good catalytic properties in variousreactionsand pyrolysis with or without

catalyst is an alluring technique to prepare bio-fuel. Nano cellulose extracted from PNs showed appealing thermal and mechanical strength. The air quality of nearbyenvironment was examinedby

studying the magnetic properties of PNs. Packing materials made of PNs showed exceptional ethylene scavenging abilities. * GUAR GUM/CARBOXYMETHYL CELLULOSE BASED ANTIOXIDANT FILM

INCORPORATED WITH HALLOYSITE NANOTUBES AND LITCHI SHELL WASTE EXTRACT FOR ACTIVE PACKAGING 2022, International Journal of Biological Macromolecules Show abstract The incorporation of

bioactive extract from the food waste into biopolymers is a promising green approach to fabricate active films with antioxidant activity for food packaging. The present study developed

bioactive antioxidant films based on guar gum/carboxymethyl cellulose incorporated with halloysite-nanotubes (HNT) and litchi shell extract (LSE). The effects of combining HNT and LSE on the

physical, mechanical, and antioxidant properties of the films were analyzed. The results showed LSE caused a reduction in tensile strength; however, the elongation at break substantially

improved from 29.93 to 62.12%. FTIR revealed covalent interaction and hydrogen bonding between guar gum/carboxymethyl cellulose and LSE. The XRD and SEM study confirmed interactions among

the polymer matrix and LSE compounds. The addition of LSE to guar gum/carboxymethyl cellulose films notably increased the UV–light barrier properties. Moreover, the antioxidant activity of

all GCH/LSE substantially improved from 9.46 to 91.52%, more than a ten-fold increase compared to composite neat GCH film. Finally, the oxidative stability of roasted peanuts packed in

fabricated GCH/LSE sachets improved after 8 days. Guar gum/carboxymethyl cellulose containing LSE as an antioxidant agent could be applied as food packaging for low water activity

oxygen-sensitive food. * BIOBASED MATERIALS FOR FOOD PACKAGING 2022, Journal of Bioresources and Bioproducts Show abstract Consumers prefer foods that are healthier with high quality and

safety. Food packaging are demanded to effectively extend the shelf-life, preserve the nutrients and decrease the microbial contamination during the transport and storage of food. With the

increasing concern on the environmental impacts caused by food packaging wastes, sustainable and green packaging are highly demanded to minimize the harmful effects of food packaging waste

on the environment. Bio-based materials are derived from sustainable and renewable biomass, instead of finite petrochemicals. The applications of bio-based materials for food packaging are

highlighted in this review. The emphasis is placed on the categories of related biobased materials, their characteristics and advantages for food packaging, as well as the strategies used to

improve their performances. Though a lot of trials have been done on biobased materials for food packaging, further attempts to improve their performances, understand the functioning

mechanisms and develop greener methods for the production, processing and destiny of these bio-based materials are still highly needed for the future research. * PINEAPPLE PEEL EXTRACT

INCORPORATED POLY(VINYL ALCOHOL)-CORN STARCH FILM FOR ACTIVE FOOD PACKAGING: PREPARATION, CHARACTERIZATION AND ANTIOXIDANT ACTIVITY 2021, International Journal of Biological Macromolecules

Citation Excerpt : The development of a novel packaging system that maintains the quality of food with the intention of shelf-life extension along with the assurance of its quality and

safety is a big challenge for scientists and the food processing industries [1,2]. Such packaging technology is called active food packaging and can be developed from polymeric materials

incorporated with active ingredients such as oxygen scavenger, antioxidant, antimicrobial, ethylene scavenger, and moisture absorber [3–5]. Active ingredients interact with the constituents

of packaged food to preserve the nutritional quality and freshness of packaged food during the distribution and storage period [6,7]. Show abstract This research study explores the

fabrication of polyvinyl alcohol (PVOH) and corn starch (ST) with pineapple peel extract (PPE) as a natural antioxidant agent, which is an abundant by-product from the food processing

industry via casting method. The effects of PPEs concentration (5%, 10%, 15%, and 20%) on the antioxidant capacity, optical, thermal, mechanical, barrier properties, and changes in

PVOH-starch molecular structure of PVOH/ST films were investigated. The results revealed that with the increasing concertation of PPEs, prepared films' thickness and water vapor

permeability slightly increased. Elongation at break of PVOH/ST films was also enhanced with PPEs concentration. All PPEs incorporated films exhibited enhanced thermal stability as the

degradation occurred above 300 °C. The addition of PPE to PVOH/ST films remarkably increased the antioxidant properties. Finally, prepared PVOH/ST/PPE films demonstrated to be a capable

material for developing active biodegradable packaging material due to its proven antioxidant activity and mechanical property, which can be helpful in the packaging of food products that

gets spoiled due to oxidation reactions. * RECENT ADVANCES IN BIOBASED AND BIODEGRADABLE POLYMER NANOCOMPOSITES, NANOPARTICLES, AND NATURAL ANTIOXIDANTS FOR ANTIBACTERIAL AND ANTIOXIDANT

FOOD PACKAGING APPLICATIONS 2022, Comprehensive Reviews in Food Science and Food Safety * EDIBLE FILMS AND COATINGS FOR FOOD PACKAGING APPLICATIONS: A REVIEW 2022, Environmental Chemistry

Letters View all citing articles on Scopus View full text © 2021 Elsevier B.V. All rights reserved.